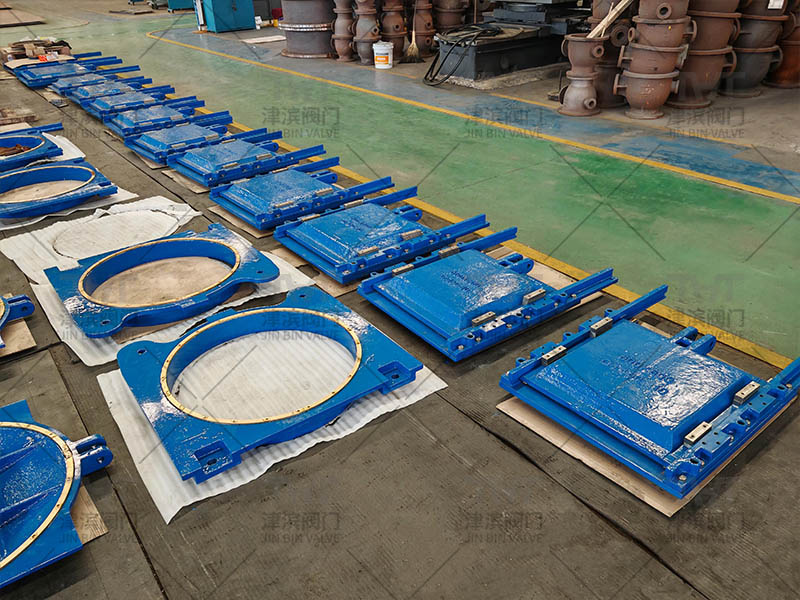

800x800 Ductile iron square sluice gate has been completed in production

Recently, a batch of square gates at the Jinbin factory have been successfully produced. The sluice valve produced this time is made of ductile iron material and covered with epoxy powder coating. Ductile iron has high strength, high toughness, and good wear resistance, and can withstand significant pressure and impact forces. The epoxy powder coating provides excellent anti-corrosion performance for the water gate, extending its service life. This material combination enables the gate to maintain stable performance in various harsh environments.

This batch of square sluice gate comes in two sizes, 600x600 and 800x800. Different sizes meet the different needs of customers and provide reliable solutions for hydraulic engineering and industrial projects. In the production process, the factory strictly controls every link, from raw material procurement to processing and manufacturing, and finally to quality inspection, to ensure that the quality of the gate meets the highest standards.

In order to ensure the accuracy and quality of the gate, the factory has adopted advanced production equipment and processes. High precision CNC machine tools ensure the dimensional accuracy of the sluice gate valve, allowing each gate to perfectly fit the installation position. Meanwhile, the professional welding process ensures the structural strength of the gate, enabling it to withstand enormous water pressure. In terms of surface treatment, the uniform coverage of epoxy powder coating not only improves the aesthetics of the gate, but also enhances its anti-corrosion performance.

The completion of this batch of square gates cannot be separated from the hard work of all the employees in the factory. From the meticulous design of designers to the skilled operation of production workers, and then to the strict supervision of quality inspectors, everyone has contributed their own strength to the production of gates. They ensure that every gate (penstock manufacturers) meets the customer's requirements with a high sense of responsibility and professionalism.

Looking ahead to the future, Jinbin will continue to adhere to the business philosophy of "quality first, customer first" and continuously improve product quality and service level. The factory will continue to increase research and development investment, launch more high-performance and high-quality products, and make greater contributions to the development of water conservancy engineering and industrial fields. At the same time, the factory will actively expand its market and establish long-term stable cooperative relationships with more customers to jointly create a better future.