Ball valve installation precautions

Ball valve is an important valve widely used in various pipeline systems, and its correct installation is of great significance to ensure the normal operation of the pipeline system and extend the service life of the ball valve.

The following are some matters that need attention during the installation of ball valves:

1. Select the right ball valve

Before installation, the appropriate ball valve electric model and specification should be selected according to the specific needs of the pipeline system to ensure that it can withstand the working pressure and working temperature, and meet the flow control requirements.

2. Check the ball valve

The motorized ball valve should be inspected before installation to ensure that there is no damage, deformation or leakage. At the same time, check whether the seal of the ball valve is intact, and replace it in time if it is worn.

3. Prepare pipelines

Before installing the metal ball valve, the pipe should be cleaned to remove impurities and dirt inside the pipe to prevent impurities from damaging the ball valve. At the same time, ensure that the pipe connection is smooth, without burrs or bumps.

4. Installation position

The installation position of the fully welded ball valve should be selected according to the design requirements of the pipeline system, usually installed in the vertical direction of the pipeline, so as to facilitate operation and maintenance. Avoid installing ball valves in environments where they are susceptible to mechanical impact or humidity.

5. Connection mode

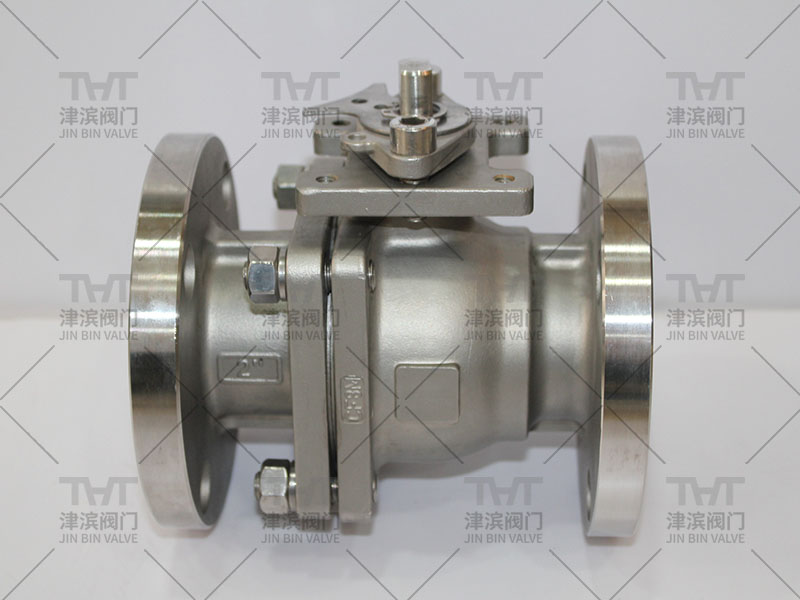

The connection between the ball float valve and the pipeline should be selected according to the design requirements, and the common connection methods are flange connection, welded connection and threaded connection. In the connection process, attention should be paid to tightness to prevent leakage.

6. Commissioning and pressure test

After the ball valve is installed, it should be adjusted and tested to ensure that the ball valve does not leak when it is closed. Pneumatic ball valve that need to be tested for sealing performance should be tested in accordance with relevant standards.

7. Operation and maintenance

During the use of the ball valve, attention should be paid to regular maintenance and maintenance, such as cleaning the ball and replacing the seal. At the same time, the operator should be familiar with the structure and use of the stainless steel ball valve to avoid damage caused by misoperation.

In short, in the ball valve installation process, should strictly abide by the relevant specifications and standards, pay attention to the details, to ensure the normal operation of the ball valve and extend the service life.

Jinbin valve provides high-quality valves for global customers, if you have related needs, you can click on the home page to contact us, looking forward to working with you!