Difference between double eccentric butterfly valve and triple eccentric butterfly valve

Double eccentric butterfly valve is that the valve stem axis deviates from both the center of the butterfly plate and the center of the body. On the basis of double eccentricity, the sealing pair of triple eccentric butterfly valve is changed into inclined cone.

Structure comparison:

Both double eccentric butterfly valve and triple eccentric butterfly valve can make the butterfly plate quickly leave the valve seat after being opened, greatly eliminate the unnecessary excessive extrusion and scraping between the butterfly plate and the valve seat, reduce the opening resistance, reduce the wear and improve the service life of the valve seat.

Material comparison:

The main pressure parts of double eccentric butterfly valve are made of ductile iron, and the main pressure parts of three eccentric butterfly valve are made of steel casting. The strength of ductile iron and steel casting are comparable. Ductile iron has higher yield strength, with a lower yield strength of 310mpa, while the yield strength of cast steel is only 230MPa. In most municipal applications, such as water, salt water, steam, etc., the corrosion resistance and oxidation resistance of ductile iron are better than that of cast steel. Due to the spheroidal graphite microstructure of ductile iron, ductile iron is better than cast steel in reducing vibration, so it is more conducive to reducing stress.

Comparison of sealing effect:

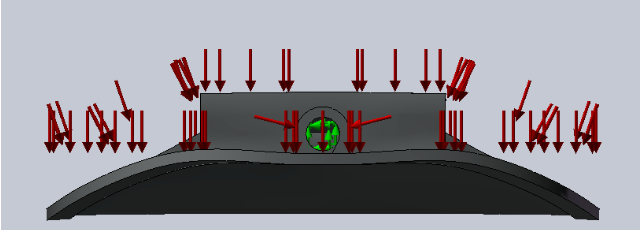

The double eccentric butterfly valve adopts spherical and floating elastic seat. Under positive pressure, the clearance caused by machining tolerance and the deformation of valve shaft and butterfly plate under medium pressure make the spherical surface of butterfly plate more closely fit on the sealing surface of valve seat. Under negative pressure, the floating seat moves towards medium pressure under medium pressure, Effectively compensate the clearance caused by machining tolerance and the deformation of valve shaft and butterfly plate under the action of medium pressure, so as to realize reverse sealing.

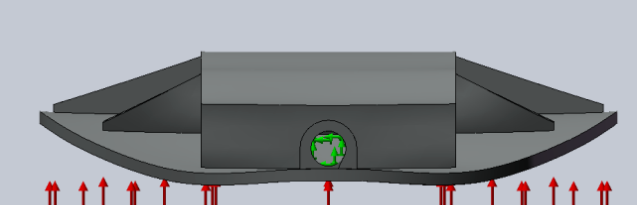

The three eccentric hard sealing butterfly valve adopts fixed inclined conical valve seat and multi-level sealing ring. Under positive pressure, the clearance caused by machining tolerance and the deformation of valve shaft and butterfly plate under medium pressure make the multi-level sealing ring more closely fit on the sealing surface of valve seat, but under reverse pressure, the multi-level sealing ring will be far away from the sealing surface of valve seat, Thus, reverse sealing cannot be achieved.