How to deal with the blackening reaction of penstock gate valve welding

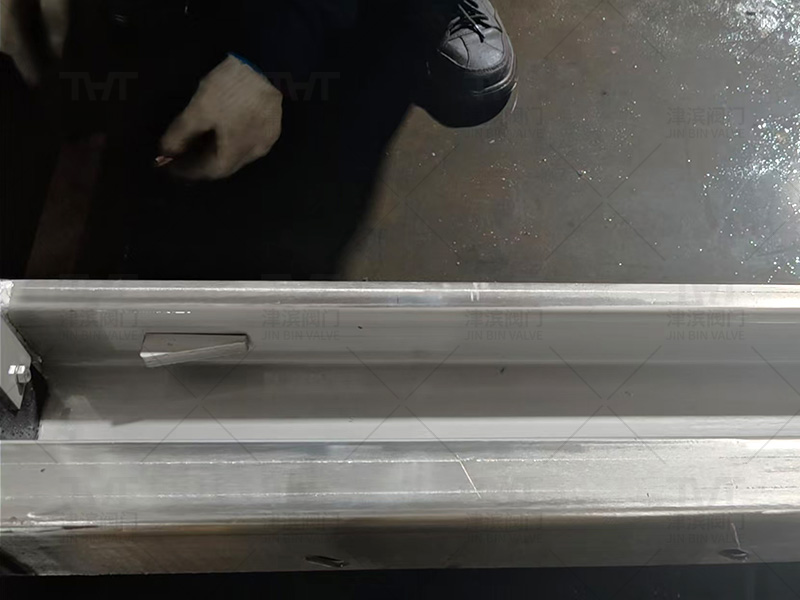

Recently, our factory is producing a batch of stainless steel sluice gates, which is a new type of wall attached gate produced by our factory, using five bending technology, small deformation and stronger sealing. After the wall penstock valve welding, there will be a black reaction, affecting the appearance, mainly due to the effect of high temperature during the welding process, so that the metal on the surface of the valve oxidizes, forming a black oxide film.

The following describes the pickling method to deal with blackening:

Jinbin factory uses electrolytic washing pickling method, using electrolytic action and chemical corrosion of acid to remove the black oxide film on the valve surface. In the electrolytic process, the valve acts as the anode, and the oxide film on the metal surface is ionized under the action of the current after being energized, forming metal ions soluble in acid solution, thus accelerating the removal of the oxide film. At the same time, the hydrogen ions in the acid react chemically with the metal oxides to dissolve them and achieve the purpose of cleaning the valve surface.

Pickling process flow:

1. Surface pretreatment: Before pickling, it is necessary to perform surface pretreatment on the valve first, such as using mechanical methods to remove oil, rust, welding slag and other impurities on the surface to ensure that the acid can fully contact the oxide film and improve the pickling effect.

Install and hang the valve correctly on the anode position of the electrolytic pickling device to ensure that the contact between the valve and the electrode is good and the current can be evenly distributed on the valve surface.

2. Prepare pickling solution: Select the appropriate acid formula and concentration according to the material and oxidation degree of the valve. Common acids are sulfuric acid, nitric acid, hydrochloric acid, etc., or a mixture of them. For example, for stainless steel valves, a mixture of nitric acid and hydrofluoric acid is often used. When configuring the acid, it is necessary to strictly follow the operating procedures, paying attention to the concentration of the acid, the temperature and the amount of additives and other parameters.

3. Electrolytic pickling: Pour the configured acid into the electrolytic cell, turn on the electrolytic power supply, and control the appropriate current density, electrolytic time and acid temperature and other parameters. Generally speaking, the greater the current density and the longer the electrolytic time, the better the removal effect of the oxide film, but at the same time, care needs to be taken to avoid excessive pickling leading to excessive corrosion of the valve surface metal. The temperature of the acid is usually controlled within a certain range, too high temperature may accelerate the volatilization and decomposition of the acid, affecting the pickling effect, and too low temperature may cause the reaction rate to be too slow.

4. Water washing: After electrolytic pickling is completed, remove the valve from the acid and quickly put it into the flowing clean water for washing to completely remove the residual acid and reaction products on the valve surface. The washing time and water flow speed should be sufficient to ensure that the pH of the valve surface reaches neutral and prevent residual acid from causing secondary corrosion to the valve.

5. Post-treatment: The valve after washing can be further treated as needed, such as passivation treatment, anti-rust treatment, etc., to improve the corrosion resistance and service life of the valve.

Jinbin Valve as a penstock manufacturer, producing all kinds of metallurgical valves, stainless steel penstock gate, large diameter gate valves, butterfly valves, etc., if you have related needs, please leave a message below or email contact us, you will receive a reply within 24 hours, looking forward to working with you!