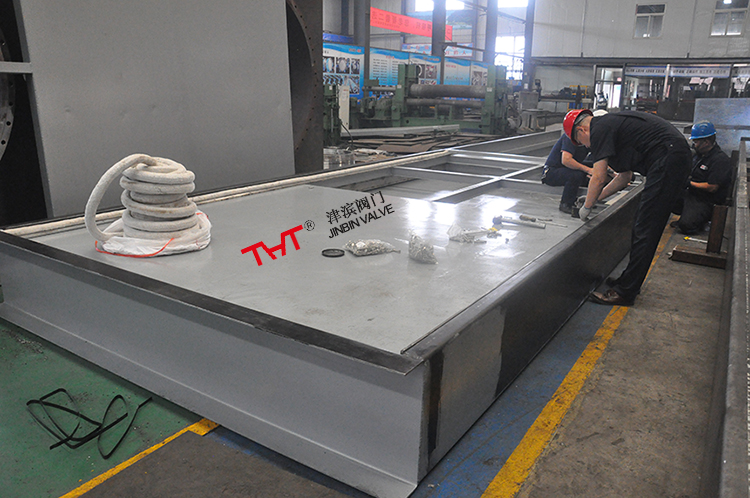

The 3500x5000mm underground flue gas slide gate was finished production

The underground flue gas slide gate supplied by our company for an steel company has been successfully delivered.

Jinbin valve confirmed the working condition with the customer at the beginning, and then the technology department provided the valve scheme quickly and accurately according to the working condition.

This project is a new flue gas slide gate. Due to the leakage problem of the original valve and it is not easy to reseal on the basis of the original valve, it is necessary to add a new valve. Each coke oven has two underground flue duct, and each underground flue duct needs to add an underground flue gas slide gate. After the slide gate is added, the original valve remains in the normally open mode. The customer requires that each part of the underground flue gas slide gateshall be designed to withstand the change of flue gas temperature from normal temperature to 350 ℃ without damage, adhesion, curl or leakage. It shall be implemented as ≤ 2% leakage. Jinbin Technology Department determines the size of the flue gas slide gate according to the number of flue duct openings and the design parameters of the underground flue duct. These flue gas slide gate are double electric actuated and double pneumatic actuated, equipped with heavy hammer, electric winch and gas storage tank. The flue gas slide gate is normally closed. This valve is mainly operated pneumatically. When the pneumatic device cannot work, it can be operated electrically. In order to ensure the sensitivity of the disc during operation, the disc is designed into two discs, and each disc is flexible without jamming when lifting up and down. At the same time, a sealing slide is set in the inner cavity of the body frame to ensure the sealing effect of the disc and reduce the shaking of the disc during lifting. In order to prevent the flue gas leakage of the disc during lifting, it is required to install a seal on the upper part of the body frame.

The flue gas slide gate can solve the problem of rapid control of flue gas pipeline in case of accident, ensure timely and efficient treatment of accident problems, and avoid greater economic losses; It can also solve the problem of manually controlling the positioning of the flue gas slide gate, and greatly reduce the labor intensity of the operators.