Damper

-

Electric Control Smoke Damper

1. High surface finish, strong and durable, high precision, more stable performance, and good quality in details

Email Details

2. In the process of valve body and valve seat processing, the Electric Control Smoke Damper appearance is not easy to be damaged, and high-precision equipment is used for processing, and the product switch is light

3. Strict quality management and quality control -

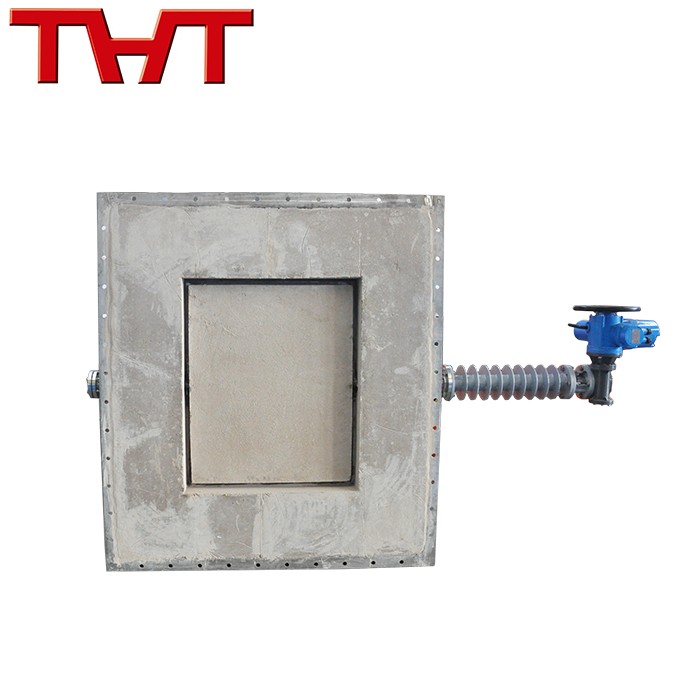

High temperature Rectangle Refractory Lined Damper Valve

The valve body with lined plate and seat. The High temperature Refractory Lined Damper Valvehas high strength, wear resistance and corrosion resistance.

Email Details

The High temperature Refractory Lined Damper Valve can be designed and manufactured into a round shape according to the needs of users, so as to meet the needs of flue with different cross-section shapes. The flue baffle is equipped with manual actuator (when the diameter is not more than 900mm, it is equipped with hand wheel mechanism), pointer and 0 ~ 90 indicator board to indicate the opening degree of valve plate.

The High temperature Refractory Lined Damper Valve can withstand high temperature of 1100 ℃ without jamming and collapse

During use, the influence of thermal expansion and cold contraction of the valve will cause the stem and packing to lock, and the valve plate and valve seat to lock. Or too much residual leads to excessive leakage rate of medium. Before processing, Jinbin valve will select the appropriate material according to the temperature, and calculate the expansion amount according to the material and thickness. Under the condition of ensuring low leakage rate, the valve will not be stuck.

In the process of use, high temperature through the stem heat conduction to the top of the stem, destroy the actuator circuit or seal ring, resulting in valve necrosis. Jinbin valve will lengthen the stem, increase heat sink, reduce the damage of high temperature to the valve -

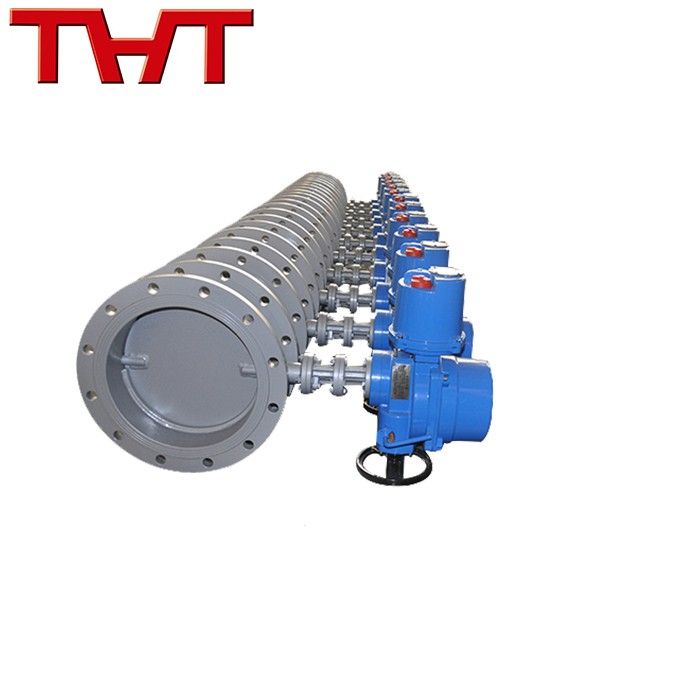

DN2800 high temperature round Refractory Lined Damper Valve

The valve body with lined plate and seat. The High temperature Refractory Lined Damper Valvehas high strength, wear resistance and corrosion resistance.

Email Details

The High temperature Refractory Lined Damper Valve can be designed and manufactured into a round shape according to the needs of users, so as to meet the needs of flue with different cross-section shapes. The flue baffle is equipped with manual actuator (when the diameter is not more than 900mm, it is equipped with hand wheel mechanism), pointer and 0 ~ 90 indicator board to indicate the opening degree of valve plate.

The High temperature Refractory Lined Damper Valve can withstand high temperature of 1100 ℃ without jamming and collapse

During use, the influence of thermal expansion and cold contraction of the valve will cause the stem and packing to lock, and the valve plate and valve seat to lock. Or too much residual leads to excessive leakage rate of medium. Before processing, Jinbin valve will select the appropriate material according to the temperature, and calculate the expansion amount according to the material and thickness. Under the condition of ensuring low leakage rate, the valve will not be stuck.

In the process of use, high temperature through the stem heat conduction to the top of the stem, destroy the actuator circuit or seal ring, resulting in valve necrosis. Jinbin valve will lengthen the stem, increase heat sink, reduce the damage of high temperature to the valve -

electric actuated three Way Damper

The Three Way Damper basically includes valve body, valve plate seat, valve plate and cylinder, The valve body is divided into three cavities a, B and C connected with the outside world by the valve plate seat. The sealing material is installed between the valve body and the valve plate seat.

Email Details

The valve plate in the cavity is connected with the cylinder through the connecting shaft, and the gas flow direction in the pipeline is changed by changing the position of the valve plate. Because of the heat exchange through the heat storage body, the working temperature of the reversing valve is low, and there is no special requirement for the material of the exchange valve. However, due to the requirements of continuous production, it is necessary to overcome the dust wear in flue gas and the influence of corrosivity. The mechanical part needs to ensure the wear caused by frequent switching of parts, which has required higher reliability and working life. -

Pneumatic Vent Butterfly Valve

1. The design is novel, reasonable, unique in structure, light in weight and quick in opening and closing.

Email Details

2. Small torque, convenient operation, labor saving and dexterous.

3. Adopt suitable materials to meet the requirements of low, medium and high medium temperature and corrosive medium. -

Electric Actuator Three Way Tee-diverter Damper

1. Our company has the leading technology of Electric Actuator Three Way Tee-diverter Damper, which can provide professional guidance for users and let customers use it at ease

Email Details

2. The Electric Actuator Three Way Tee-diverter Damper is divided into pneumatic, hydraulic and electric according to the operation way to meet the different needs of customers

3. The Electric Actuator Three Way Tee-diverter Damper adopts high-quality steel plate welding structure, with small volume, light weight and small resistance. The material flow can be quickly switched by using electric (hydraulic) technology -

High Temperature Electric Damper Butterfly Valve

High Temperature Electric Damper Butterfly Valve is characterized by high temperature resistance, high pressure range and large nominal diameter. The valve body is made of stainless steel, and the sealing ring of valve plate adopts metal ring instead of rubber ring.

Email Details

High Temperature Electric Damper Butterfly Valve is made of steel plate welding, which is mainly used for flue gas duct and gas pipeline with high temperature medium. -

electric actuated Smoke Air Damper Valve

1. High quality carbon steel welding, small and light, easy to decorate. Double design of anastomotic part, strengthen firmly.

Email Details

2. The butterfly disc is made of double-layer high-quality heat-resistant high-temperature alloy steel, and the inner cavity is cooled by water.

3. Due to the vertical structure of the middle line, the butterfly plate has large over-current area, small current resistance, flexible switch, convenient operation, time-saving and labor-saving

4. If the temperature is too high, add heat sink to the neck to cool down and protect the driving device.

5. High temperature resistance, small volume, flexible rotation and convenient use -

Blast Gate Slide Damper

1. Easy to operate and low cost

Email Details

2. Compact structure and easy operation

3. Welded structure, low leakage rate