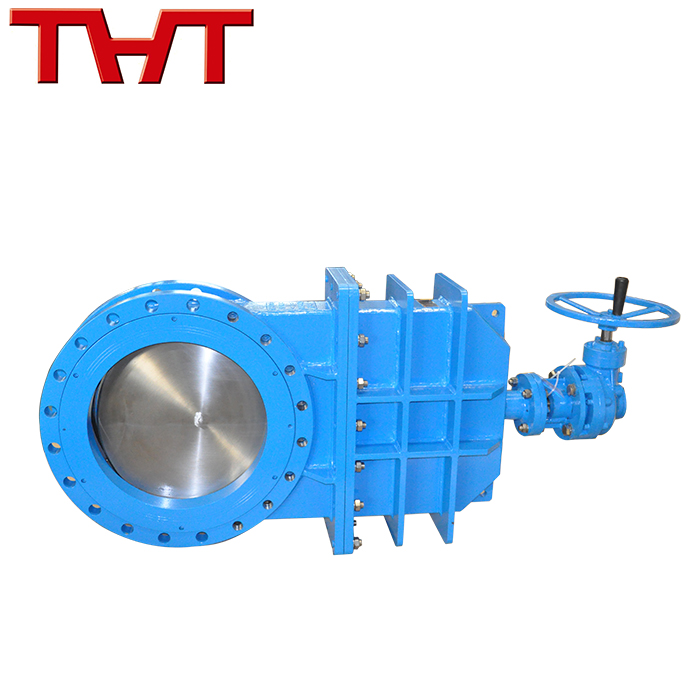

API Standard cast steel Knife Gate Valve

- THT

- China

- 30 Days

- 50

knife gate valve used lost foam casting technology,one step molding,low cost and reliable casting quality.

Jinbinvalve apply float retaining ring for cast steel knife gate valve seal, which design ensured bi-directional of the valve.

The roller shaped stem ensures that the valve can be operated easily even under the maximum pressure.

knife gate valve can be installed in the middle of the pipe or at the end of the pipe. The structure is firm and can be used without reducing the pressure level.

API Standard cast steel Knife Gate Valve

The body of knife gate valve is made by lost foam,low cost and reliable casting quality.It is suitable for media such as pulp stock , chemicals , sludge , bio mass , slurry and water.

| Nominal pressure | 150lb |

| Test pressure | Shell: 1.5 times rated pressure Sealing: 1.1 times rated pressure |

| Suitable temperature | -29°C to 325°C |

| Suitable fluid | Slurry, waste water etc. |

| Connection ends | ASME B16.5 150lb flange ends |

| Body | WCB |

| Gate | SS304 |

| Sealing | EPDM/NBR/VITON |

| Stem | 2Cr13 |

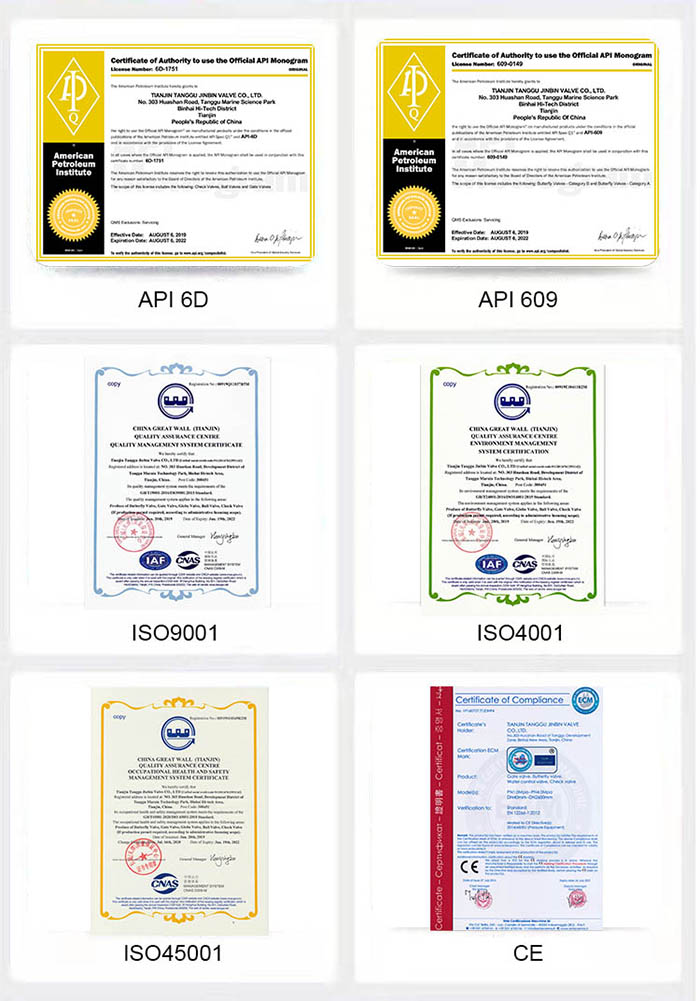

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment such as physical.