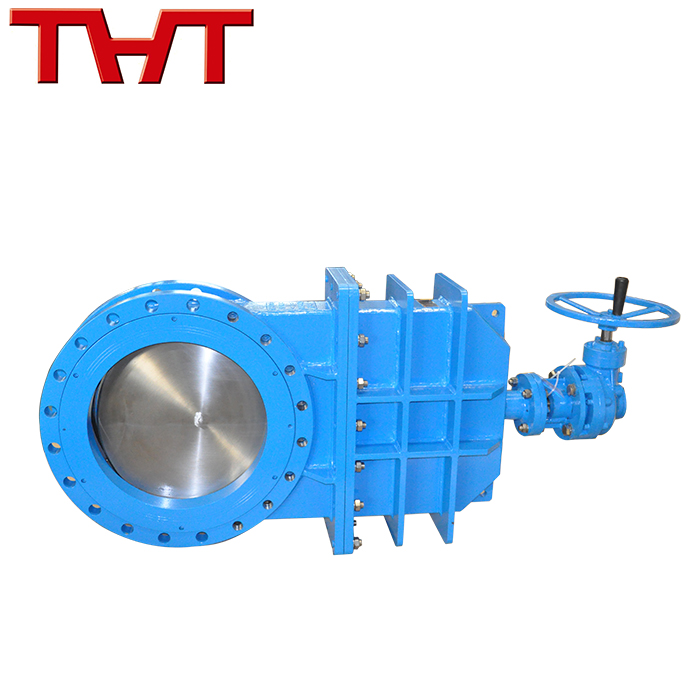

Electrically Actuated Knife Gate Valve

- THT

- China

- 30 Days

- 200

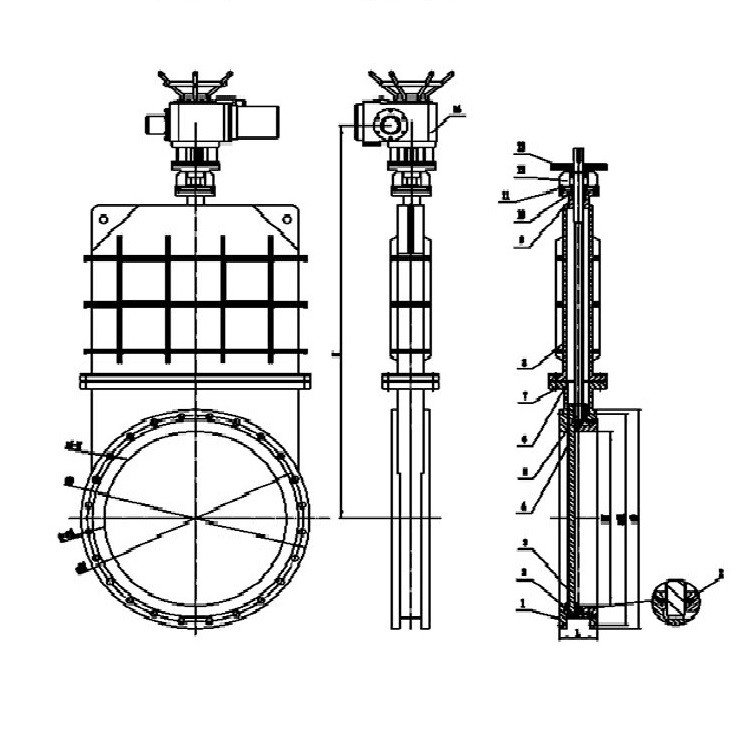

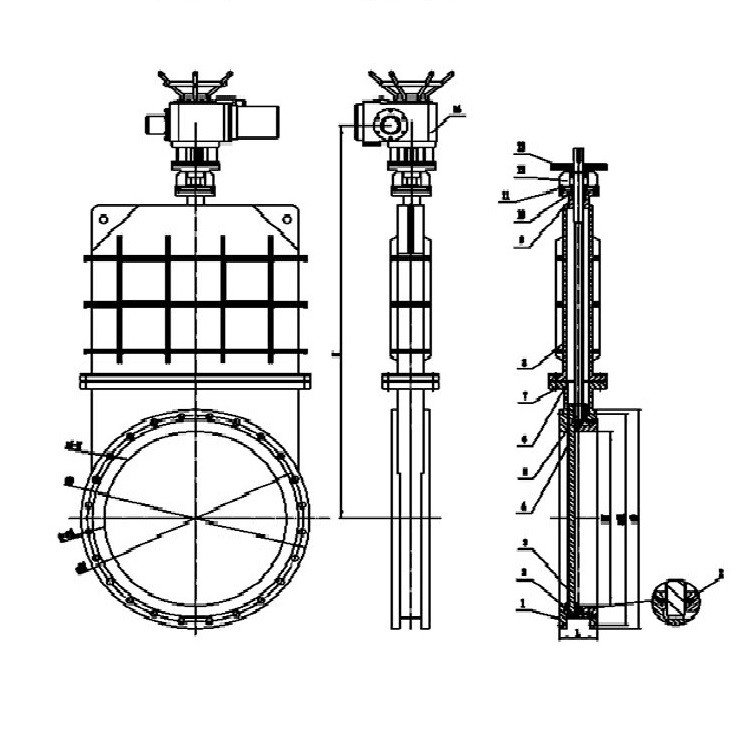

Electric knife gate valve has the advantages of simple structure, beautiful appearance, full diameter channel and small flow resistance coefficient. When the ram is lifted, the sticky matter on the sealing surface is scraped off, and the sundries are automatically removed;

Stainless steel gate can prevent seal leakage caused by corrosion. The whole stainless steel material prevents corrosion damage and has long service life;

The electrically actuated knife gate valve can choose various pipe flange standards and flange sealing surface type, and can also choose various driving modes such as manual, worm gear drive, electric, pneumatic, hydraulic, etc., to meet the different needs of users.

Bare Stem Knife Sluice Gate Valve

Electric knife gate valve produced by Jinbinvalve is double disc for high working pressure. The movement direction of the gate is perpendicular to the flow direction. The electrically actuated knife gate valve can only be fully opened and fully closed, impossible usedto be adjusted and throttled. Knife gate valve, as the name implies, is a flat valve plate with a knife shaped oblique cut at the bottom, which has the function of cutting off the medium, so that the valve can be closed without being blocked by medium. This valve is generally used for pulp, coal ash, chemical raw materials, sewage, food and other media circulation. The pressure range is generally less than 1.6Mpa, and the temperature is generally below 120 ℃,. According to the sealing performance requirements can be divided into soft seal and hard seal. The soft seal can reach zero leakage, and the hard seal can be inspected according to different leakage levels. The valve has the advantages of convenient operation, free opening, flexible and reliable movement, simple disc assembly and maintenance, reasonable sealing structure and convenient and practical replacement of sealing ring.

DN200-DN1800

DN200-DN900 10Bar

DN1000-DN1800 8Bar

EN1092 PN10 PN16

ANSI-16.5(150LB)

JIS-5K 10K

Other end connection on request

| Body | Q235B / GGG40/GGG50 |

| Disc | SS304 |

| Seat | EPDM/NBR/VITON |

| Stem | 2Cr13/304 |

| Operator | Electric/Penumatic/Hydraulic |

MPa | DN | L | D | D1 | D2 | H | N-M | W(Kg) |

200 | 100 | 335 | 295 | 265 | 700 | 8-M20 | 45 | |

250 | 110 | 390 | 350 | 320 | 840 | 12-M20 | 58 | |

300 | 110 | 440 | 400 | 368 | 960 | 12-M20 | 70 | |

350 | 110 | 500 | 460 | 428 | 1110 | 16-M20 | 110 | |

400 | 130 | 565 | 515 | 482 | 1250 | 16-M22 | 155 | |

450 | 140 | 615 | 565 | 532 | 1380 | 20-M22 | 268 | |

500 | 140 | 670 | 620 | 585 | 1530 | 20-M22 | 320 | |

600 | 150 | 780 | 725 | 685 | 1800 | 20-M27 | 400 | |

700 | 170 | 895 | 840 | 800 | 2150 | 24-M27 | 581 | |

800 | 180 | 1010 | 950 | 898 | 2420 | 24-M30 | 723 | |

900 | 203 | 1110 | 1050 | 1005 | 2680 | 28-M30 | 1045 | |

1000 | 203 | 1220 | 1160 | 1115 | 3100 | 28-M30 | 1730 | |

1200 | 223 | 1450 | 1380 | 1325 | 3450 | 32-M36 | 3650 | |

1600 | 254 | 1220 | 1160 | 1115 | 3100 | 28-M30 | 3400 | |

1800 | 276 | 1450 | 1380 | 1325 | 3450 | 32-M36 | 4500 | |

2000 | 320 | 2325 | 2230 | 2150 | 5010 | 48-M48 | 5700 |