Hydraulic Knife Gate Valve

- THT

- China

- 30 Days

- 200

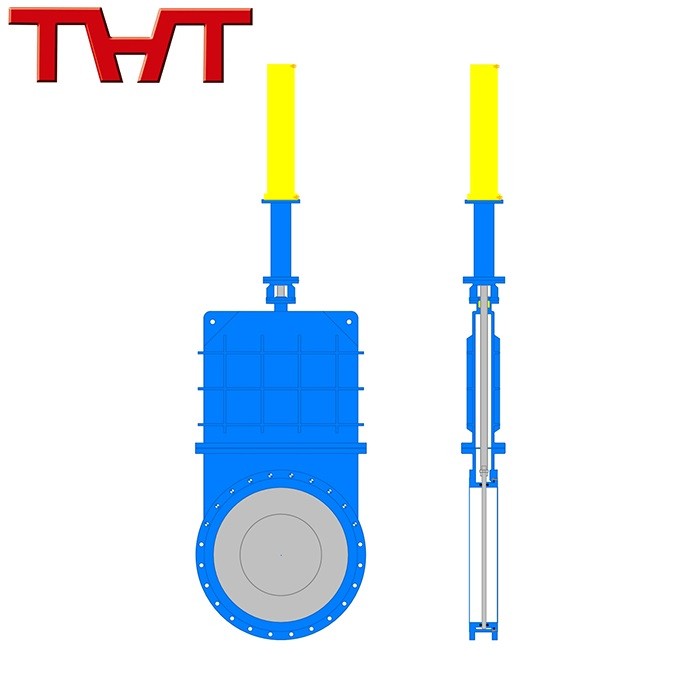

The hydraulic knife gate valve structure includes a valve body, a gate and a U-shaped sealing strip,

When the valve is closed, the gate moves downward, and the bottom edge of the gate contacts with the sealing strip, thus compressing the sealing strip into the groove to realize the sealing of the valve body and the gate;

When the hydraulic knife gate valve is opened, the gate moves up, the bottom edge of the gate is separated from the sealing strip, and the sealing strip springs up and is flat with the groove, which can prevent the medium sediment from accumulating in the groove of the valve body, which is not easy to be blocked and has no residue, and the pipeline cleaning is convenient, so as to effectively improve the sealing effect of the knife gate valve and prevent leakage when the valve is closed.

The hydraulic knife gate valve has longer service life and simpler maintenance. The sealing surface of flange is inlaid with O-ring without additional flange gasket. The installation is simple and convenient, the friction coefficient is small, and the opening and closing are flexible.

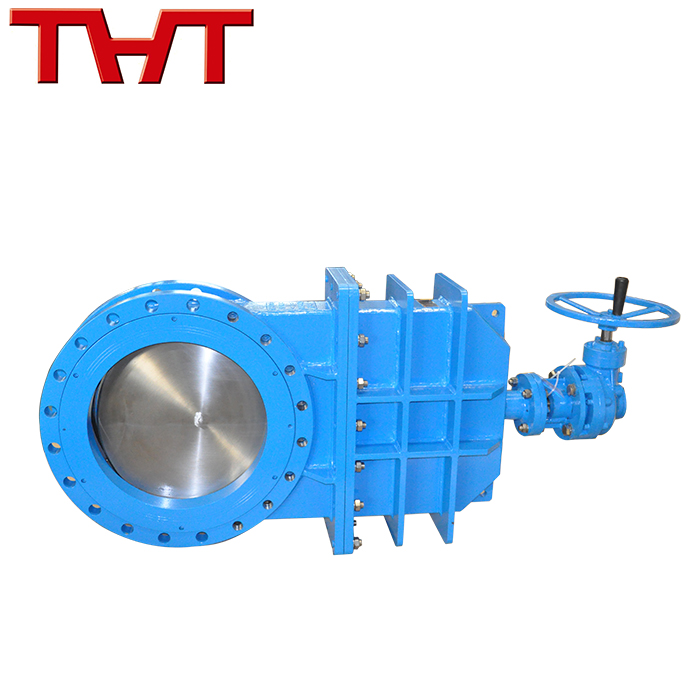

Hydraulic Knife Gate Valve

Hydraulic is connected with the valve gate by the piston rod of the hydraulic cylinder. Its operation principle is to manually drive the handle of the hydraulic pump to press the hydraulic oil into the upper and lower cavities of the hydraulic cylinder through the manual reversing valve to drive the piston rod to do up and down action, thus driving the gate to open and close to achieve the valve opening and closing function.

Mining, iron and steel industry - used for coal slurry, filter slurry, etc.

Purification device - used for waste water, mud, dirt and clarified water with suspended solids.

Paper industry - for any concentration of pulp, feed water mixture.

Sugar industry - used for beet washing, syrup, juice, juice, etc.

Food industry - for washing and washing equipment, grain conveying equipment, malt pulp, etc.

Power plant ash removal - for ash slurry.

DN200-DN1800

Design and manufacturing standards:JB/T 8691-2013

Structural length standard: GB / T 12221-2005

Connection flange standard: GB / T 9113

Pressure and temperature class: GB / T 12224-2005

Test and inspection standard: GB / T 13927-2008

DN200-DN900 10Bar

DN1000-DN1800 8Bar

| Body&Bonnet | Carbon steel Q235B |

| Disc | SS304 |

| Seat | EPDM/NBR/VITON |

| Stem | 2Cr13/304 |

| Operator | Hydraulic |

MPa | DN | L | D | D1 | D2 | H | N-M | W(Kg) |

200 | 100 | 335 | 295 | 265 | 700 | 8-M20 | 45 | |

250 | 110 | 390 | 350 | 320 | 840 | 12-M20 | 58 | |

300 | 110 | 440 | 400 | 368 | 960 | 12-M20 | 70 | |

350 | 110 | 500 | 460 | 428 | 1110 | 16-M20 | 110 | |

400 | 130 | 565 | 515 | 482 | 1250 | 16-M22 | 155 | |

450 | 140 | 615 | 565 | 532 | 1380 | 20-M22 | 268 | |

500 | 140 | 670 | 620 | 585 | 1530 | 20-M22 | 320 | |

600 | 150 | 780 | 725 | 685 | 1800 | 20-M27 | 400 | |

700 | 170 | 895 | 840 | 800 | 2150 | 24-M27 | 581 | |

800 | 180 | 1010 | 950 | 898 | 2420 | 24-M30 | 723 | |

900 | 203 | 1110 | 1050 | 1005 | 2680 | 28-M30 | 1045 | |

1000 | 203 | 1220 | 1160 | 1115 | 3100 | 28-M30 | 1730 | |

1200 | 223 | 1450 | 1380 | 1325 | 3450 | 32-M36 | 3650 | |

1600 | 254 | 1220 | 1160 | 1115 | 3100 | 28-M30 | 3400 | |

1800 | 276 | 1450 | 1380 | 1325 | 3450 | 32-M36 | 4500 | |

2000 | 320 | 2325 | 2230 | 2150 | 5010 | 48-M48 | 5700 |