RTO Rotary Valve

- THT

- China

- 30 days

- 30/month

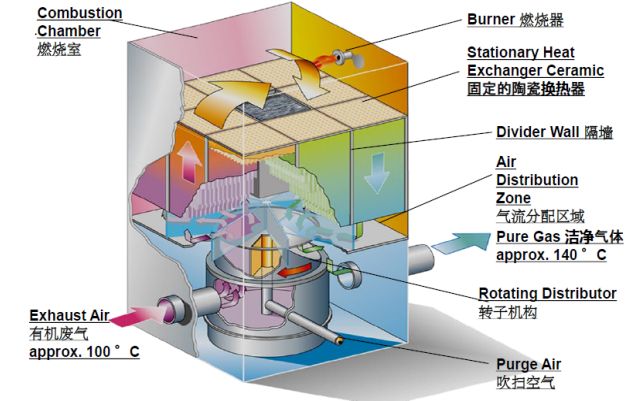

Relying on the switching valve in the existing regenerative combustion device, each regenerator in the traditional device will be equipped with three switching valves to realize the use functions of inlet, outlet and cleaning of the regenerator. In the process of use, the control program between the valves is complex, the switching is difficult, and the daily maintenance is cumbersome. Moreover, the setting of this valve leads to large concentration fluctuation and pressure fluctuation in the regenerator.

Therefore, how to design a valve which is easy to control, easy to switch, high practical value, and can reduce the concentration fluctuation and pressure fluctuation in the regenerator is an urgent problem to be solved in the cause of environmental protection.

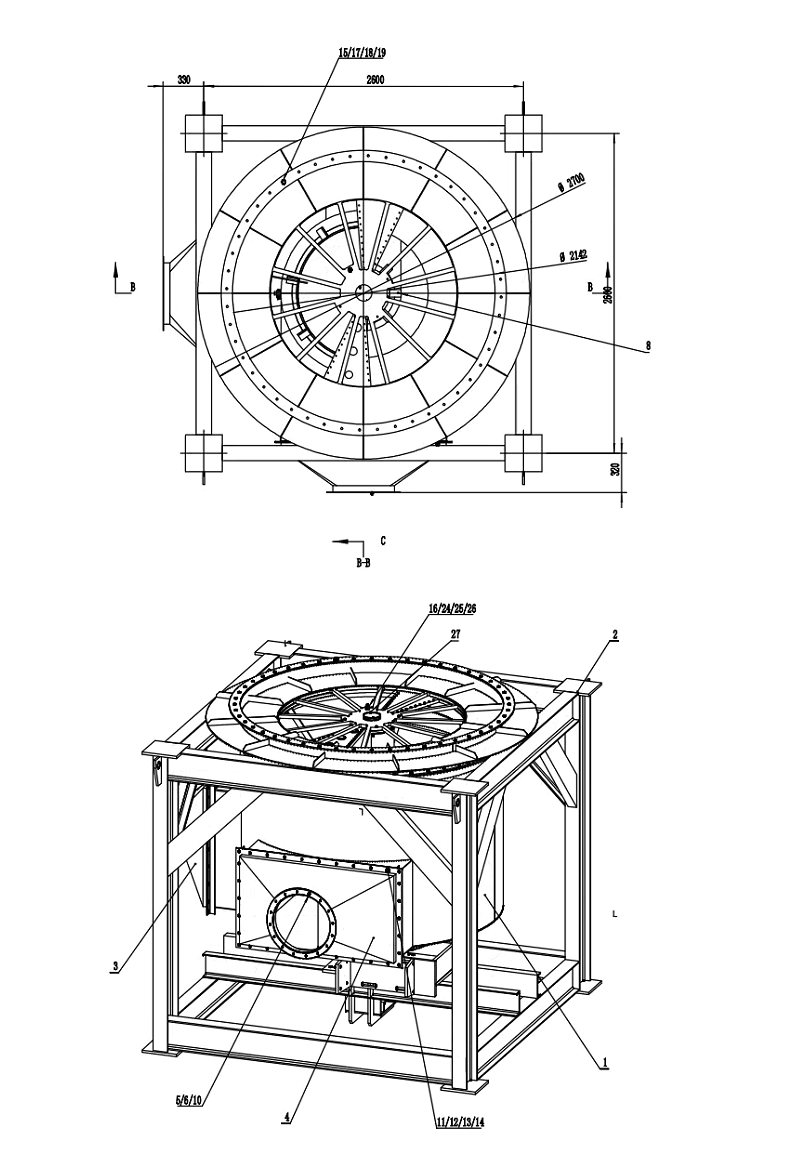

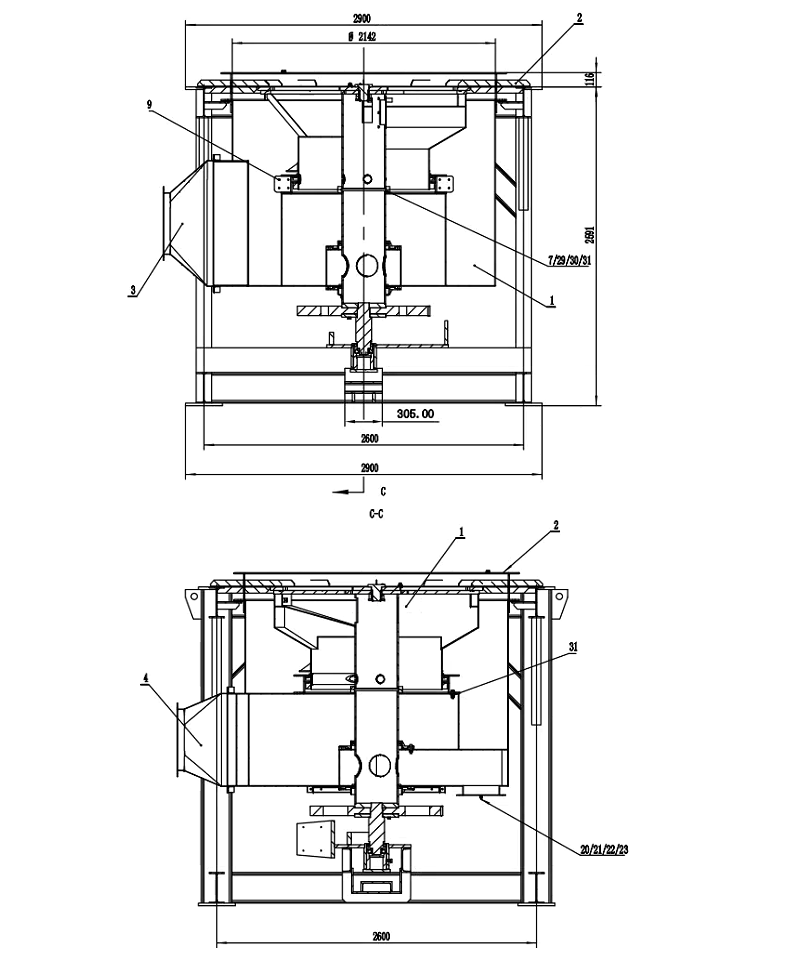

RTO Rotary Valve

In order to solve the above technical problems, the utility model discloses an RTO heat storage combustion rotary valve, which comprises an air inlet (1), an air outlet (2), an air inlet and outlet switching runner (3), a seal structure (4), a cleaning nozzle (5), an encoder (6), a coupling (7) and an electric machine (8). The motor (8) is located at the bottom of the valve, connected with the coupling (7) and controlled by the encoder (6) to drive the operation and rotation of the cleaning nozzle (5) and the inlet and outlet gas switching runner (3). The air inlet (1) and air outlet (2) are respectively arranged on both sides of the valve to receive waste gas and transmit clean gas. The device is also provided with a seal structure (4) to improve the air tightness of the rotary valve.

| Name | RTO Rotary Valve |

Size | DN200-DN2800 |

| Pressure | 0.1Mpa |

| Medium | Solid particles, dust |

| Temperature | ≤450℃ |

| Operation | Electric |

| Body | carbon steel |

| Gate | carbon steel |

| Shaft | 20Cr13 |

| Packing | Flexible graphit |

| Bolts | stainless steel A2-70 |

| Handwheel | WCB |

| Sealing material | stainless steel |

Suitable material

| Body | Carbon steel/stainless steel/Duplex steel |

| Gate | Carbon steel/stainless steel/Duplex steel |

| Shaft | SS304/SS316/20Cr13 |

| Packing | Flexible graphite |

| Bolts&nuts | Stainless steel A2-70 |

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment such as physical.