Slurry Knife Gate Valve Manufature

- THT

- China

- 30 Days

- 200

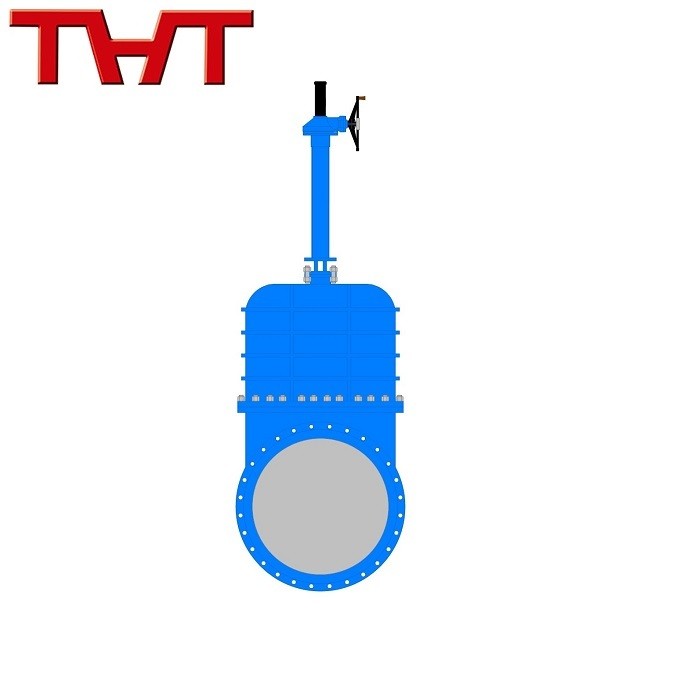

This series standard, lug type wafer knife gate vale are suitable for the sewage treatment, the chemical industry, the manufacture paper pulp industry and the mining industry ,coal washingndustry, to circulates the medium for pipeline in and so on liquid suspending iquidze plays cuts off and clears the role.

The lug knife gate valve use the single side to force to seal, not only se als reliably, moreover maremove the deposition to meet the seal requirements. The valve body material is cast ir on, carbon steel, stainless steel and teflon, satisfiedly resists corrosion, anti- rubs and so on the different request.

This wafer lug knife gate valve structural length short, the weight is light. The installment and the service is all convenient.

Slurry Knife Gate Valve Manufacture

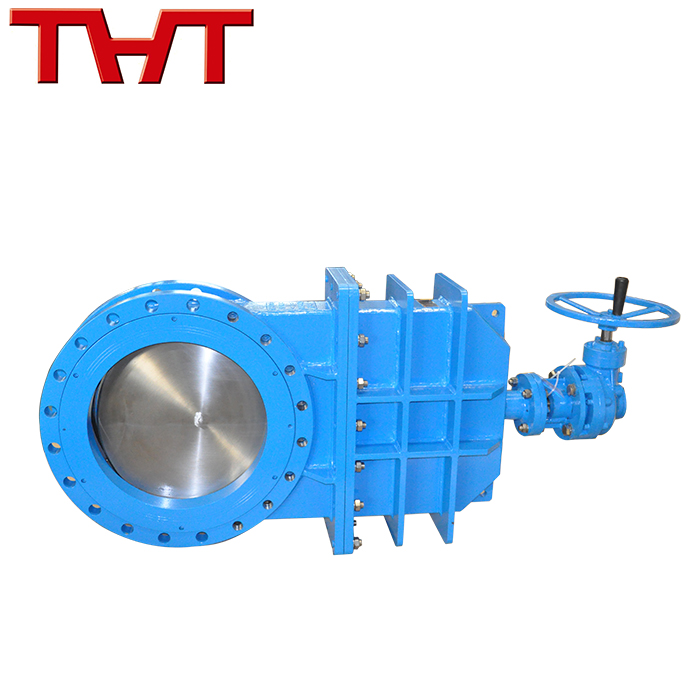

The slurry knife gate valve is a uni-directional valve deals with flow in one direction , while offering 0 leakage of rubber seal. The u-shape peripheral seat design ensures full-port flow and non-clogging shutoff . It is suitable for media such as pulp stock , chemicals , sludge , bio mass , slurry and water.

Size | DN200-DN1800 |

| Pressure | DN200-DN900 10Bar DN1000-DN1800 8Bar |

| Ends connection |

|

| Medium | Slurry, water, waste water |

| Temperature | ≤120℃ |

| Operation | handwheel |

| Body | Q235B / GGG40/GGG50 |

| Disc | SS304 |

| Seat | EPDM/NBR/VITON |

| Stem | 2Cr13/304 |

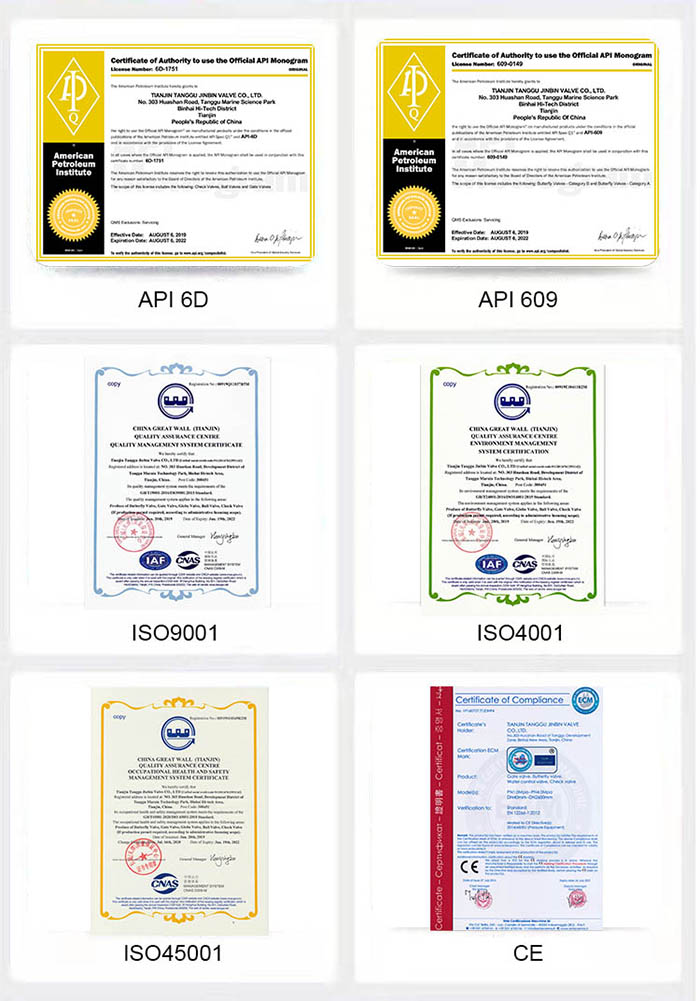

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment such as physical.