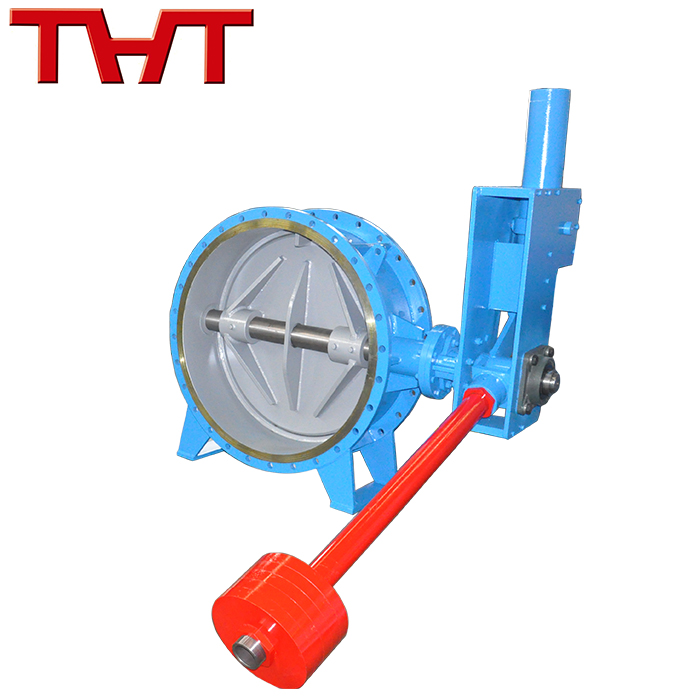

24 Inch Worm Gear Operated Eccentric Butterfly Valve

- THT

- Tianjin,China

- 30 days

- 3000

This worm gear butterfly valve has short structure size, small size, light weight and light operation.

The 24 inch butterfly valve adopts a triple eccentric structure, which has the function of closing and tightening when closed. The butterfly plate can bear pressure in both directions, with excellent sealing performance and zero leakage. After opening, the sealing surface is completely out of contact and protects the sealing surface from damage.

The body valve seat structure is adopted, which reduces the direct contact of the valve seat with the medium, thereby reducing the degree of erosion of the valve seat and extending the service life of the valve seat.

24 Inch Worm Gear Operated Eccentric Butterfly Valve

This worm gear operated butterfly valve is installed in the diameter direction of the pipeline. The multi-layer sealing ring is fixed on the valve plate. Compared with the traditional butterfly valve, this kind of butterfly valve has high temperature resistance, light operation, no friction when opening and closing. When closing, the torque of the transmission mechanism increases to compensate the sealing, which improves the sealing performance of the butterfly valve. And the advantages of extending the service life.

Features:

1. The eccetric butterfly valve seat is laminated by stainless steel flakes and graphite flakes. This structure can effectively prevent the influence of small solids in the medium and the sealing surface seizure caused by thermal expansion. Even if there is a small damage, it will not leak

2. The fixing method of the sealing pair adopts the elliptical distribution of bolts, which not only locates accurately, but also makes each bolt receive a balanced force, preventing the loosening and leakage of the sealing pair caused by uneven stress distribution.

3. Various piping flange standards and flange sealing surface types can be selected, and various drive modes such as manual, worm gear, electric, pneumatic, and hydraulic can also be selected to meet different needs of users.

1. Design&manufature standard:JB/T 8527 API609

2. Face to face dimension:GB/T 12221

3. End connection:GB/T 12224 EN1092

4. Inspection&testing:GB/T 13927 API598

| DN | DN200-DN2400 | ||

| PN | 1.0/1.6/2.5/4.0 | MPa | |

| Test | Shell | PN*1.5 | MPa |

| Seal | PN*1.1 | MPa | |

| Working temperature | -29 ~ 425℃ | ||

| Suitable medium | water,sewage | ||

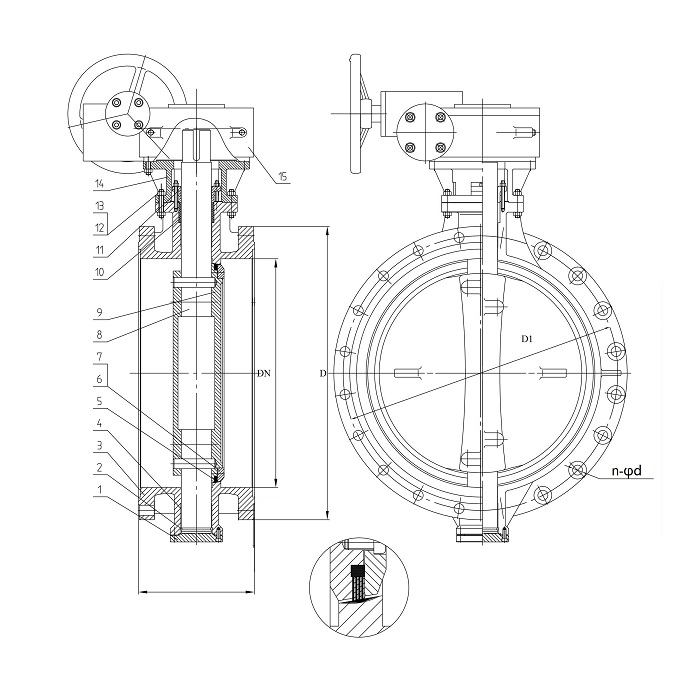

| Part name | Material |

| 1.End cover | Q235 |

| 2.Open loop ring | 2Cr13 |

| 3.Body ring | Cr13 |

| 4.Bushing | SF-1 |

| 5.Seal ring | 304+Graphite |

| 6.Press plate | A105 |

| 7.Bolt | 304 |

| 8.Stem | 2Cr13 |

| 9.Disc | WCB |

| 10.Packing | Flex.graphite |

| 11.Packing gland | WCB |

| 12.Bolt | 304 |

| 13.Nut | 304 |

| 14.Bracket | WCB |

| 15.Actuator |

| PN | DN | L | D | D1 | H | n-φd |

| 1.6MPa | 200 | 152 | 268 | 295 | 850 | 12-22 |

| 250 | 165 | 320 | 355 | 1000 | 12-25 | |

| 300 | 178 | 370 | 410 | 1100 | 12-26 | |

| 350 | 190 | 430 | 470 | 1237 | 16-26 | |

| 400 | 216 | 482 | 525 | 1276 | 16-30 | |

| 450 | 222 | 545 | 585 | 1365 | 20-30 | |

| 500 | 229 | 609 | 650 | 1435 | 20-34 | |

| 600 | 267 | 720 | 770 | 1595 | 20-41 | |

| 700 | 292 | 800 | 840 | 1840 | 24-41 | |

| 800 | 318 | 905 | 950 | 2080 | 24-41 | |

| 900 | 330 | 1005 | 1005 | 2350 | 28-41 | |

| 1000 | 410 | 1110 | 1117 | 2680 | 28-48 | |

| 1200 | 470 | 1330 | 1390 | 2850 | 32-54 |