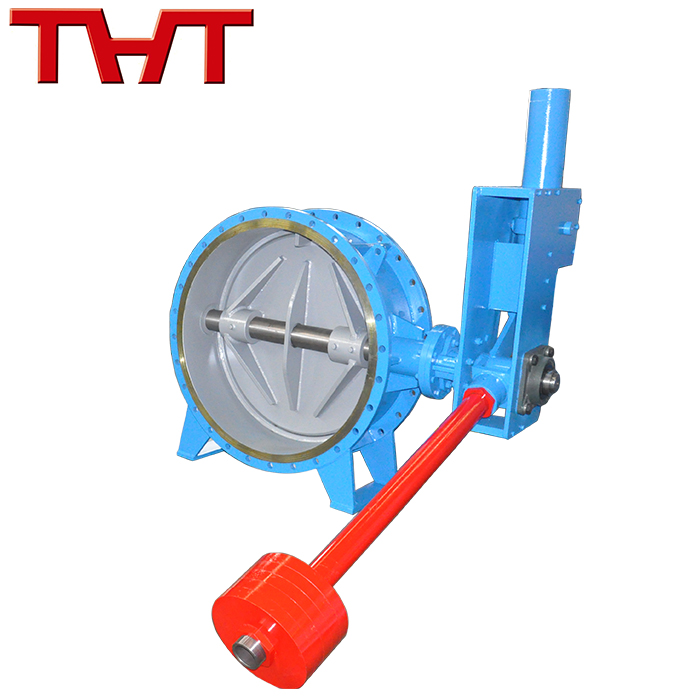

DN250 NBR Seat Iron Butterfly Valve

- THT

- Tianjin,China

- 30 days

- 3000

The DN250 wafer butterfly valve have small size and light weight. Easy instllation and mintenance. Itcan be mounted wherever nedded.

The NBR seat butterfly valve siple and compact construction, small torque when open and close,quick go degrees on-off operation.

This kind of butterfly valve is energy saving and flow curve tending to straight line. Excellent regulation performance and long service life. Standing the test of tens of thousands openingclosing operations.

DN250 NBR Seat Iron Butterfly Valve

The NBR seat iron butterfly valve is used for throttling or shutting off the flow of corrosive or non corrosive gased, liquids and semi liquid. It can be installed in any selected position in pipelines in the industries of petroleum processing, chemicals, food, medicine, textile, paper making, hydroelectricity engineering, building, water supply and sewage, metallurgy, energy engineering as well as light industry.

Features:

1. The NBR seat butterfly valve have bubbles-tight sealing with no leakage under the pressure test.Wide selection of materials, applicable for various mdeium.

2. The DN250 butterfly valve disc is linked by no line gum, function is morereliable.

Technical requirements:

1. Design&manufature standard:JB/T 8527

2. Face to face dimension:GB/T 12221

3. End connection:GB/T 12224

4. Inspection&testing:GB/T 13927

| DN | DN200-DN1000 | ||

| PN | 1.0/1.6 | MPa | |

| Test | Shell | PN*1.5 | MPa |

| Seal | PN*1.1 | MPa | |

| Working temperature | -15 ~ 100℃ | ||

| Suitable medium | water,sewage,oil,gas | ||

| Part name | Material |

| Body | WCB/GGG40/50/CF8/CF8M/CF3/CF3M |

| Disc | WCB/GGG40/50/CF8/CF8M/CF3/CF3M |

| Seat | EPDM/NBR/VITON/PTFE |

| Stem | 2Cr13/F304/F316/316L |

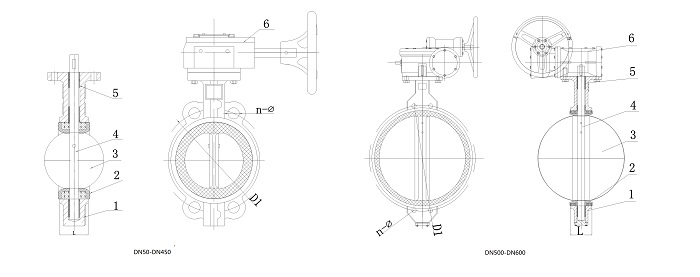

| PN | DN | L | D1 | n-φ |

| 1.6MPa | 50 | 42 | 125 | 4-19 |

| 65 | 44 | 145 | 4-19 | |

| 80 | 46 | 160 | 4-19 | |

| 100 | 50 | 180 | 4-19 | |

| 125 | 54 | 210 | 4-19 | |

| 150 | 54 | 240 | 4-23 | |

| 200 | 59 | 295 | 4-23 | |

| 250 | 64 | 355 | 4-28 | |

| 300 | 74 | 410 | 4-28 | |

| 350 | 74 | 470 | 4-28 | |

| 400 | 86 | 525 | 4-31 | |

| 450 | 103 | 585 | 4-31 | |

| 500 | 130 | 650 | 4-34 | |

| 600 | 150 | 770 | 4-37 |