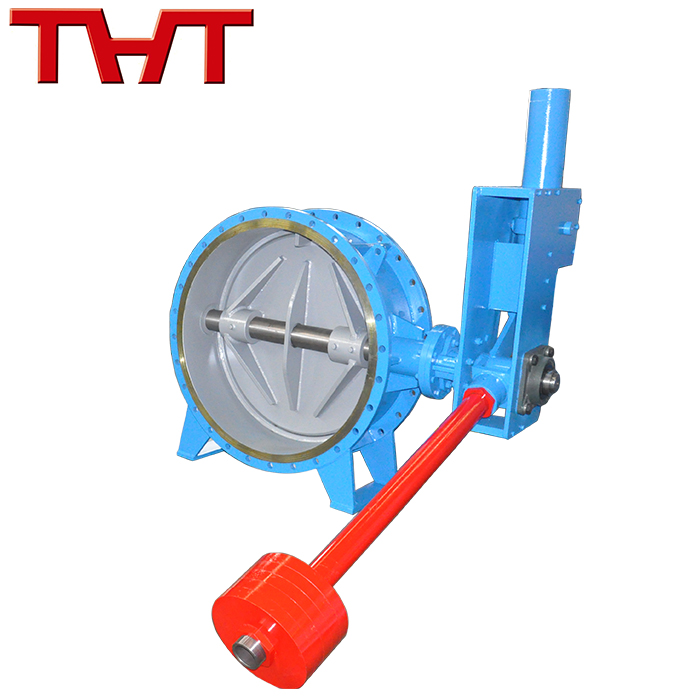

Electric Welded Ends Butterfly Valve

- THT

- Tianjin,China

- 30 days

- 3000

This welded ends butterfly valve design makes the valve an ideal hard seal butterfly valve for bubble sealing in high temperature, high pressure and fire protection applications.

Due to the welding structure, without flange,and no need counter flange,the valve welded to pipe directly by welding rod,so finally the valve can achieve leakage in the pipeline.

This valve has no flange, while saving costs and it is convenient and very beautiful for piping and thermal insulation.

Electric Welded Ends Butterfly Valve

This welded butterfly valve is suitable for petroleum, chemical, food, medicine, metallurgy, shipping, papermaking, industrial environmental protection, water supply and drainage, high-rise building pipeline. It can be used to open and close or adjust medium flow in a variety of corrosive and non corrosive gas, liquid, liquid and solid powder pipelines and containers.

Features:

The welded butterfly valve seal ring can use soft rubber and hard laminated metal sheet, which has the dual advantages of metal hard seal and elastic seal. It has excellent sealing performance no matter at low temperature or high temperature.

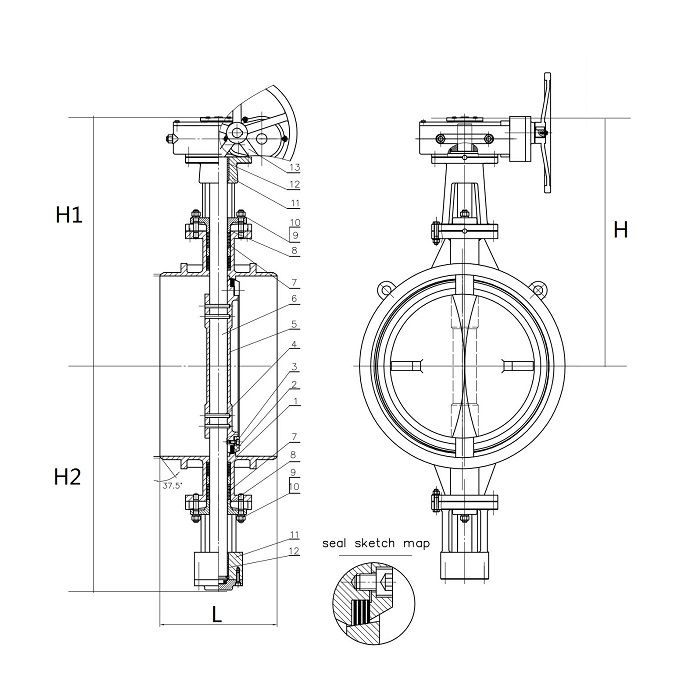

With three-dimensional eccentric structure, the valve seat and butterfly plate have almost no friction, with the sealing function of more close

The electric welded butterfly valve sealing surface of valve body is made of hardfacing stainless steel and cobalt based cemented carbide, which is wear-resistant and has long service life.

Unique structure, flexible operation, labor-saving, convenient, not affected by high and low ring pressure, reliable sealing performance.

Technical requirements:

Design&manufature standard:JB/T 8527

Face to face dimension:GB/T 12221

End connection:GB/T 12224

Inspection&testing:GB/T 13927

Performance parameter:

| DN | DN200-DN2400 | ||

| PN | 1.0/1.6/2.5/4.0 | MPa | |

| Test | Shell | PN*1.5 | MPa |

| Seal | PN*1.1 | MPa | |

| Working temperature | -29 ~ 425℃ | ||

| Suitable medium | water,sewage,oil,ga | ||

| Part name | Material |

| Body | WCB/CF8/Q235/A105 |

| Disc | WCB/CF8/Q235/A105 |

| Seat | 304+Graphite |

| Stem | 2Cr13 |

Main dimensions:

| PN | DN | L | H1 | H2 | H | D0 |

| 1.6MPa | 200 | 230 | 260 | 205 | 307 | 160 |

| 250 | 250 | 295 | 235 | 337 | 200 | |

| 300 | 270 | 340 | 275 | 392 | 200 | |

| 350 | 290 | 383 | 309 | 435 | 250 | |

| 400 | 310 | 427 | 346 | 481 | 300 | |

| 450 | 330 | 467 | 392 | 521 | 400 | |

| 500 | 350 | 499 | 427 | 568 | 400 | |

| 600 | 390 | 618 | 509 | 689 | 500 | |

| 700 | 430 | 745 | 572 | 903 | 500 |

Product display: