High Performance BS Stainless Steel Butterfly Valve

- THT

- Tianjin,China

- 30 days

- 3000

The high performance butterfly valve is no need to add O-rings and metal parts to assist the sealing. The lip-type sealing structure can compensate for changes in temperature and pressure to the valve. There is almost no friction when sealing, ensuring smaller torque and better sealing.

BS butterfly valve use of a single PTFE valve seat design has good elasticity and high reliability. The lip-type sealing structure can compensate for changes in temperature and pressure, with long service life, small maintenance, and two-way air-free sealing.

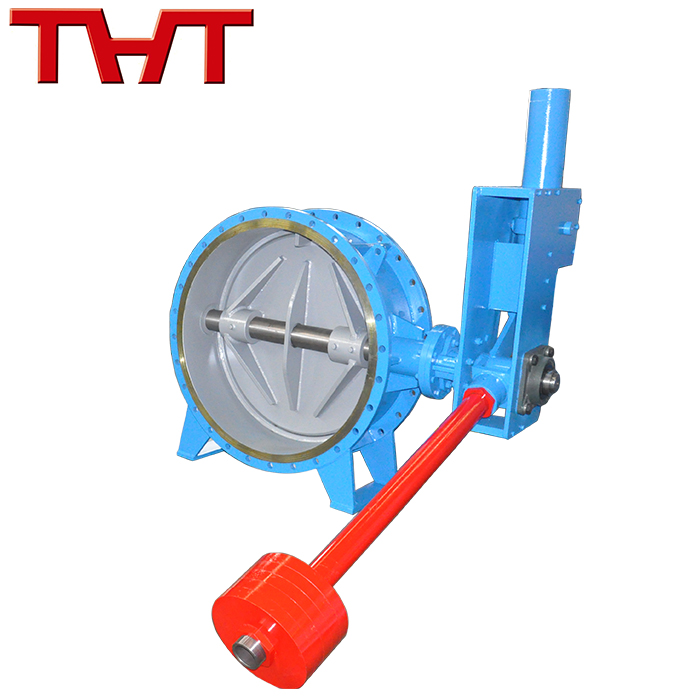

High Performance BS Stainless Steel Butterfly Valve

1. The outside of the high performance butterfly valve seat is a movable insert. The tighter the flange clamp and the greater the pressure, the better the sealing performance. It is convenient and simple to replace the valve seat. The valve seat can be taken out by removing the insert without disassembling the valve plate and valve shaft. It adopts double eccentric butterfly plate with spherical sealing surface, and is equipped with a single piece of flexible lip sealing seat, which is suitable for occasions requiring reliable sealing and good adjustment characteristics. Due to the design of the double eccentric butterfly plate, the valve has a tight sealing performance and a long service life. It can be used to quickly cut off or adjust the flow.

2. The stainless steel butterfly valve is suitable for the transportation of liquid and gas (including steam) in various industrial pipelines. Specially selected, it can also be used in special media, such as chlorine, oxygen, high vacuum, sulfur-resistant or corrosive media. The connection method can be a wafer type or a lug type single flange design used for large pipe diameters and pipeline ends.

Features:

1. The high performance butterfly valve eccentric shaft and eccentric disc are designed so that the valve seat does not contact the discwhen it is opened and in the middle position.

2. There are no wear points on the upper and lower parts of the stainless steel butterfly valve seat, low torque, and small requirements for the operating mechanism.

Technical requirements:

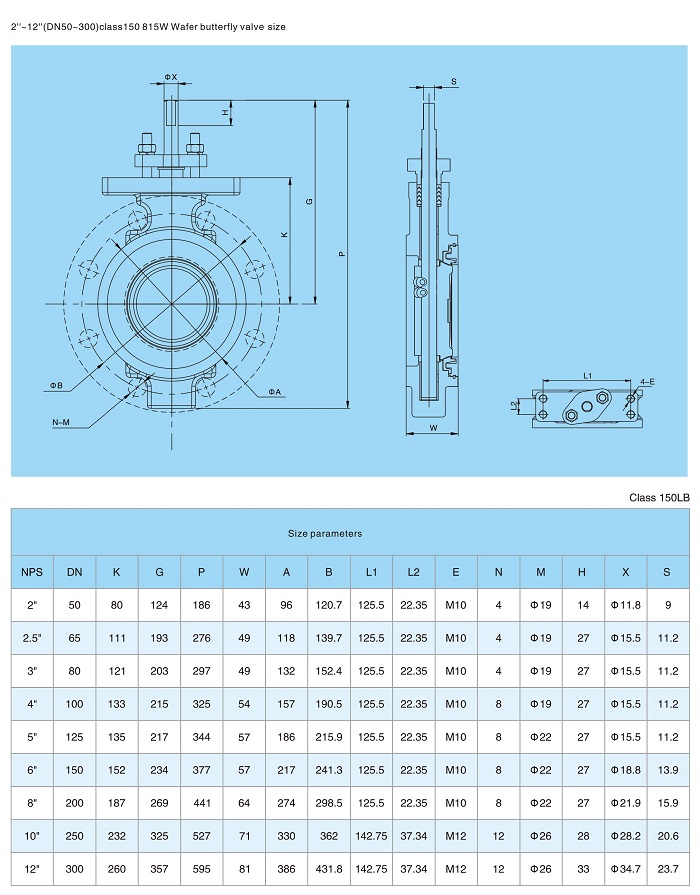

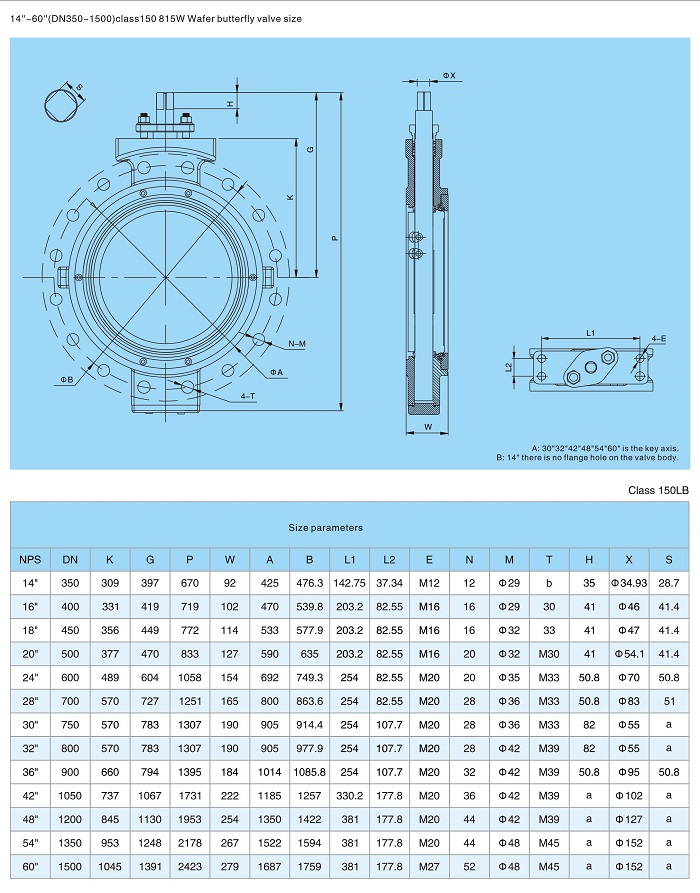

1. Design&manufature standard:JB/T 8527

2. Face to face dimension:GB/T 12221

3. End connection:GB/T 12224

4. Inspection&testing:GB/T 13927

| DN | DN200-DN1500 | ||

| PN | 150/300 | LB | |

| Test | Shell | 3.0/6.0 | LB |

| Seal | 2.2/4.4 | LB | |

| Working temperature | -20 ~ 100℃ | ||

| Suitable medium | water,sewage,oil,gas | ||

| Part name | Material |

| Body | WCB/CF8/CF8M/CF3M |

| Disc | CF8/CF8M/CF3M |

| Seat | PTFE/RPTFE/PPL |

| Stem | 17-4PH |

Product display: