High Temperature SS316 Three Eccentric Butterfly Valve

- THT

- Tianjin,China

- 30 days

- 3000

This SS316 butterfly valve adopts a triple eccentric structure, which has a tighter sealing function as it closes, and its sealing performance is reliable.

The eccentric butterfly valve sealing material is made of stainless steel + asbestos board with long service life.

The stainless steel + asbestos plate sealing ring can be located on the valve body or on the butterfly plate. It can be applied to media with different characteristics for users to choose.

The high temperature butterfly valve used outside bearing, this design can avoid the bearing lock due to high temperature and the valve cannot be opened normally.

High Temperature SS316 Three Eccentric Butterfly Valve

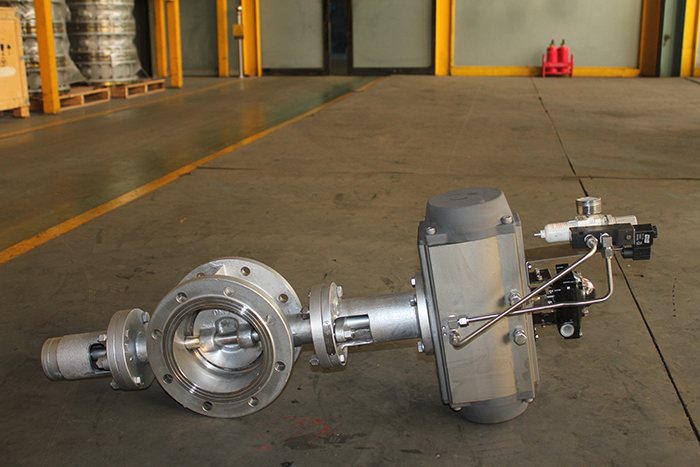

The three eccentric butterfly valve with solenoid valve, air source treatment triple piece, limit switch, positioner and other pneumatic components. Pneumatic hard-sealed butterfly valve, compact structure, easy 90° rotary switch, reliable sealing, and long service life. It is widely used in the water supply and drainage of water plants, power plants, steel mills, papermaking, chemical, catering and other systems as adjustment and cut-off .

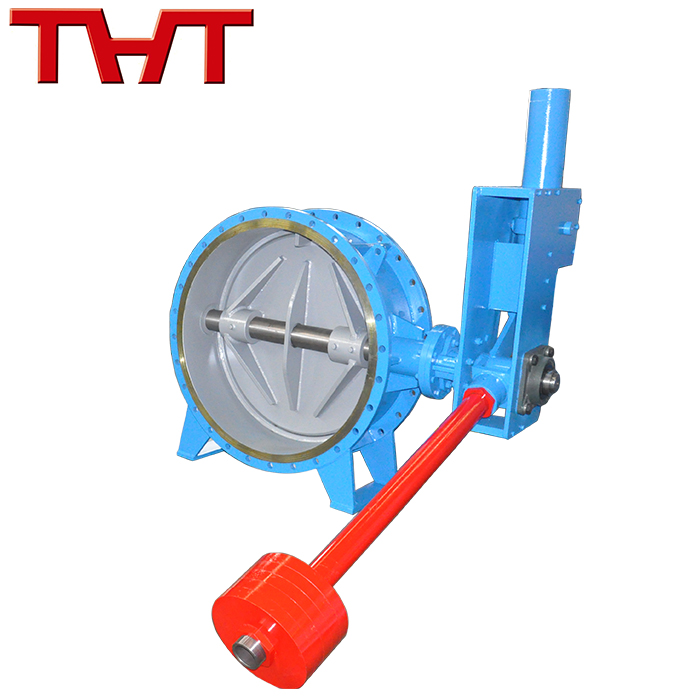

1. The SS316 butterfly disc adopts a frame structure with high strength, large flow area and low flow resistance.

2. The overall baking varnish can effectively prevent corrosion and can be used in different media as long as the sealing material of the sealing valve seat is replaced.

3. This high temperature butterfly valve has a two-way sealing function. It is not controlled by the flow direction of the medium during installation and is not affected by the spatial position. It can be installed in any direction.

4. This triple eccentric butterfly valve has unique structure, flexible operation, labor saving and convenient.

1. Design&manufature standard:JB/T 8527

2. Face to face dimension:GB/T 12221

3. End connection:GB/T 12224

4. Inspection&testing:GB/T 13927

| DN | DN200-DN2400 | ||

| PN | 1.0/1.6/2.5/4.0 | MPa | |

| Test | Shell | PN*1.5 | MPa |

| Seal | PN*1.1 | MPa | |

| Working temperature | -29 ~ 425℃ | ||

| Suitable medium | water,sewage,oil,ga | ||

| Part name | Material |

| Body | WCB/CF8/Q235/A105 |

| Disc | WCB/CF8/Q235/A105 |

| Seat | 304+Graphite |

| Stem | 2Cr13 |

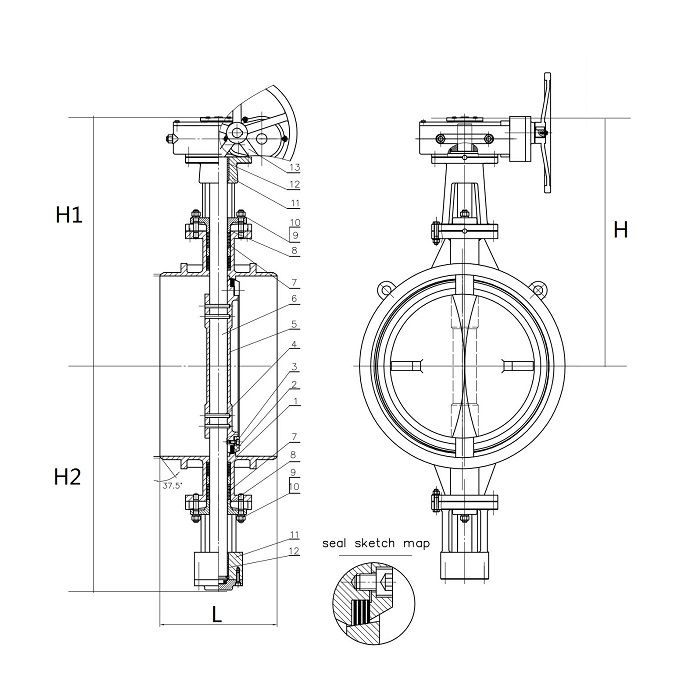

| PN | DN | L | H1 | H2 | H | D0 |

| 1.6MPa | 200 | 230 | 260 | 205 | 307 | 160 |

| 250 | 250 | 295 | 235 | 337 | 200 | |

| 300 | 270 | 340 | 275 | 392 | 200 | |

| 350 | 290 | 383 | 309 | 435 | 250 | |

| 400 | 310 | 427 | 346 | 481 | 300 | |

| 450 | 330 | 467 | 392 | 521 | 400 | |

| 500 | 350 | 499 | 427 | 568 | 400 | |

| 600 | 390 | 618 | 509 | 689 | 500 | |

| 700 | 430 | 745 | 572 | 903 | 500 |