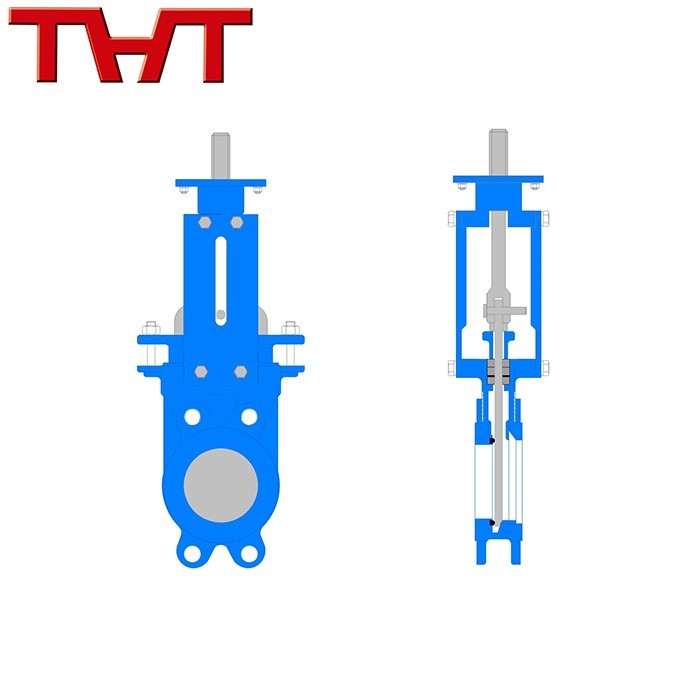

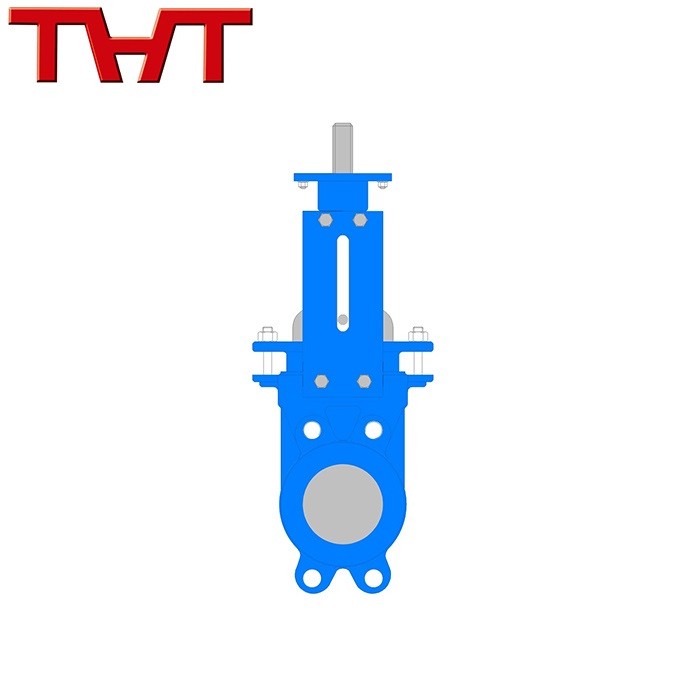

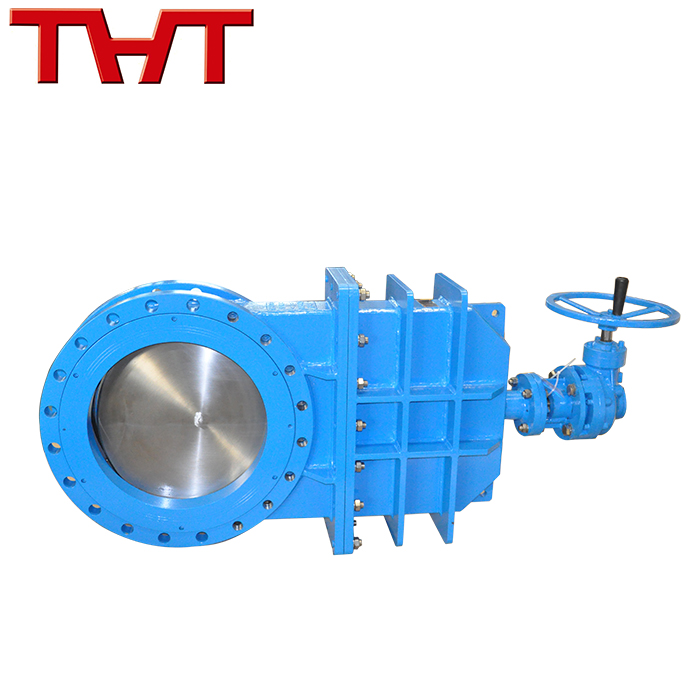

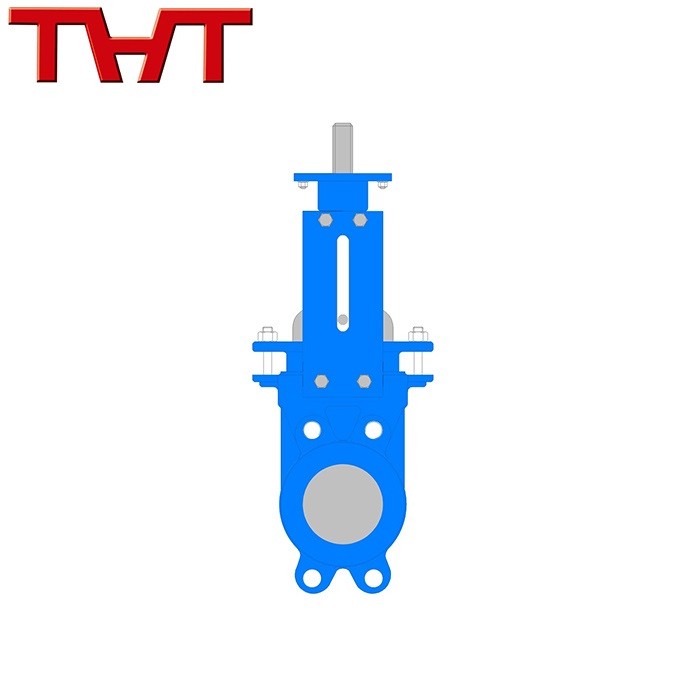

Rising Stem Knife Gate Valve

- THT

- China

- 30 Days

- 2000

1. The knife gate valve adopts integral design, with small fluid resistance and flexible and convenient operation.

2. The screw drive of manual knife gate valve adopts double plane bearing design, which greatly reduces the transmission friction and makes the valve open easily and smoothly.

3. Movable seal is used for the sealing seat of knife gate valve, and O-ring pre tightening is used to provide pre tightening force, which makes the sealing seat close to the valve disc, greatly reduces the leakage, and has automatic compensation function for the wear of sealing pair in long-term use, so as to improve the service life.

4. Fixed guide claw, no groove design, not easy to cause media accumulation or jamming.

5. The valve seat can choose metal hard seal or soft seal according to the needs of medium and working condition: the surface of the gate is treated with chromium plating or ion nitriding to make the gate more wear-resistant and the service life of the sealing surface longer; Soft seal can be PTFE seat or reinforced PTFE seat or EPDM, NBR, good sealing and corrosion resistance.

6. Wide range of media: good sealing performance, strong economic practicability, manual operation, pneumatic operation, electric operation, wide range of application.

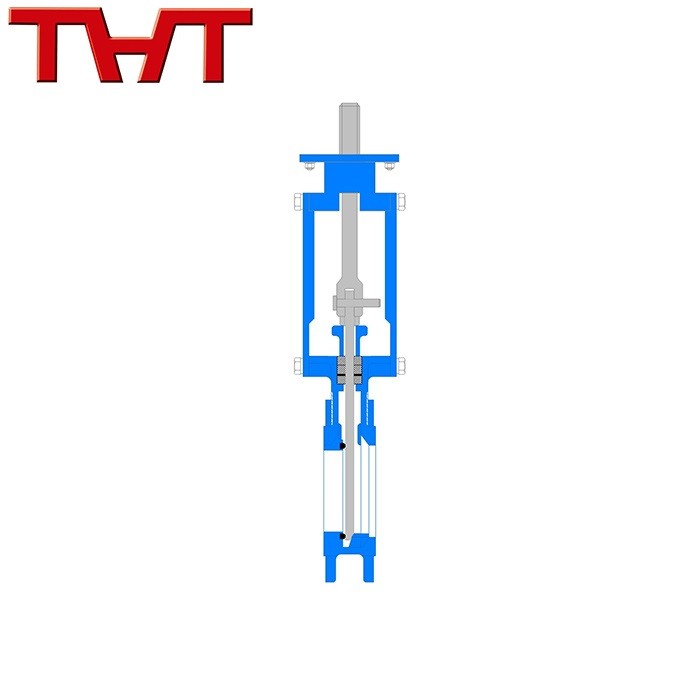

Rising Stem Knife Gate Valve

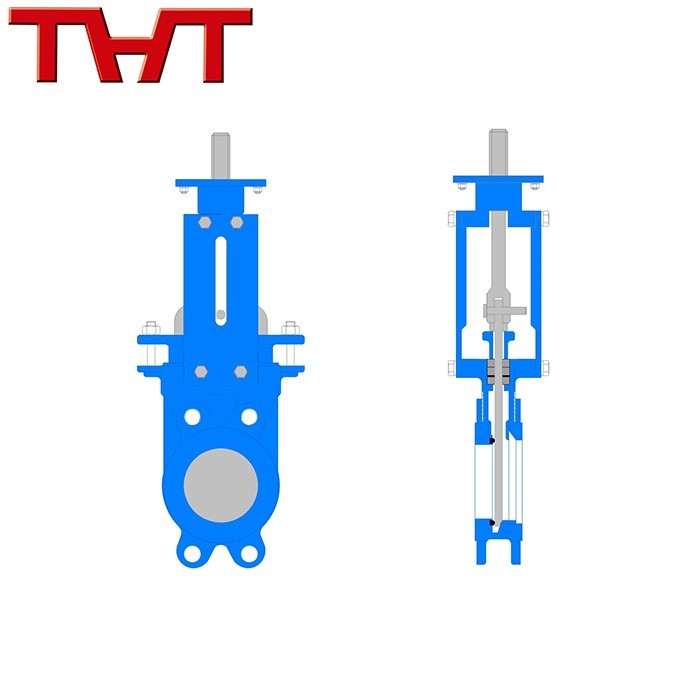

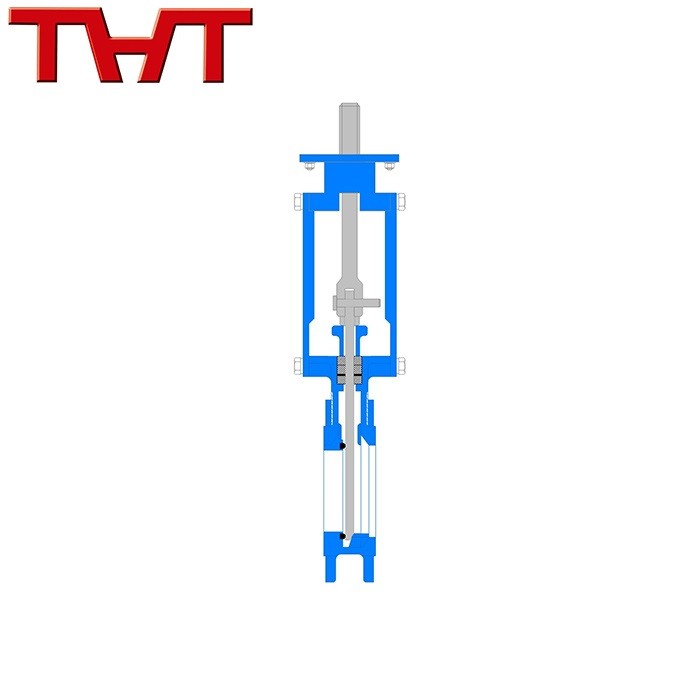

Rising stem knife gate valve is a kind of knife gate valve structure with replaceable rubber sealing ring. The sealing principle is mainly to achieve the sealing effect through the close contact between the ram and the rubber sealing ring. The main feature of this structure is that the rubber sealing ring is encapsulated in the stepped groove on the valve seat, and the sealing ring is inversely locked by the metal spring structure, so that the sealing ring and the ram switch will not fall off during the sealing process, And the sealing ring is broken, you can take off the metal pressure sleeve and replace the rubber sealing ring at will. The efficiency of the valve is greatly improved. It is an economical and effective high performance product. This series of knife gate valves can be equipped with pneumatic actuators to meet different industrial and mining requirements.

| Suitable size | DN50-DN1200mm |

| Nominal pressure | PN10 |

| Test pressure | Shell: 1.5 times rated pressure Sealing: 1.1 times rated pressure |

| Suitable temperature | -10°C to 100°C |

| Suitable fluid | Slurry, waste water etc. |

| Operation | Manual,Electric,Pneumatic |

| Connection ends | BS EN1092 flange ends |

| Body | GGG40 |

| Disc | SS304 |

| Seat | NBR / EPDM / SS304 |

| Stem | SS420 |

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment such as physical.