knife gate valve factory

-

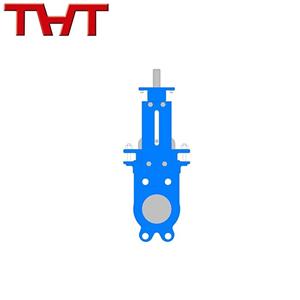

Bare Stem flange ends bi-directional sealing Knife Gate Valve

Knife gate valve with bare stem suitable for pneumatic, electric and hydraulic actuators, customized according to customer requirements,customers can specify different brands of actuators. Bare stem knife gate valve has the advantages of small torque, short face to face dimensions and simple operation.According to different actuators, equipped with corresponding control panel or connected with PLC board, can carry out local control and remote control. The welded body bare stem knife gate valve can make large diameter , from DN200-DN1800, and from design to manufature, we have QC check every step quality, to make sure the final finish bare shaft knife gate valve have perfect performance,finally make the customer satisfied.

Email Details -

wafer ductile iron Knife Gate Valve

Non-rising stem knife gate valve have a stem nut on the disc,when turn the stem by hand,the disc will go up and down with the stem nut,this design used where the installation space is limited. We have some large diameter knife sluice gate valve body in stocked,so we can provide short lead time for our customers. All the flange knife gate valve will tested one by one before shipping,test according to API598 GB/T13927 ext. Body test 1.5*PN,seal test 1.1*PN, if the knife gate valve is bi-directional, then we will test two side of seal.

ductile iron knife gate valve China Knife Sluice Gate Valve wafer Knife Gate Valve Factory ggg40 knife gate valveEmail Details -

Rising Stem Knife Gate Valve

1. The knife gate valve adopts integral design, with small fluid resistance and flexible and convenient operation. 2. The screw drive of manual knife gate valve adopts double plane bearing design, which greatly reduces the transmission friction and makes the valve open easily and smoothly. 3. Movable seal is used for the sealing seat of knife gate valve, and O-ring pre tightening is used to provide pre tightening force, which makes the sealing seat close to the valve disc, greatly reduces the leakage, and has automatic compensation function for the wear of sealing pair in long-term use, so as to improve the service life. 4. Fixed guide claw, no groove design, not easy to cause media accumulation or jamming. 5. The valve seat can choose metal hard seal or soft seal according to the needs of medium and working condition: the surface of the gate is treated with chromium plating or ion nitriding to make the gate more wear-resistant and the service life of the sealing surface longer; Soft seal can be PTFE seat or reinforced PTFE seat or EPDM, NBR, good sealing and corrosion resistance. 6. Wide range of media: good sealing performance, strong economic practicability, manual operation, pneumatic operation, electric operation, wide range of application.

Email Details