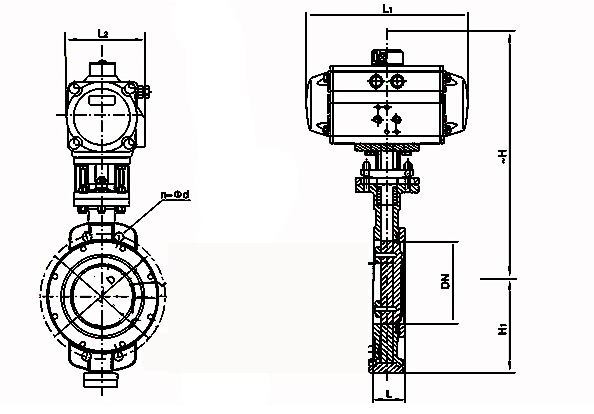

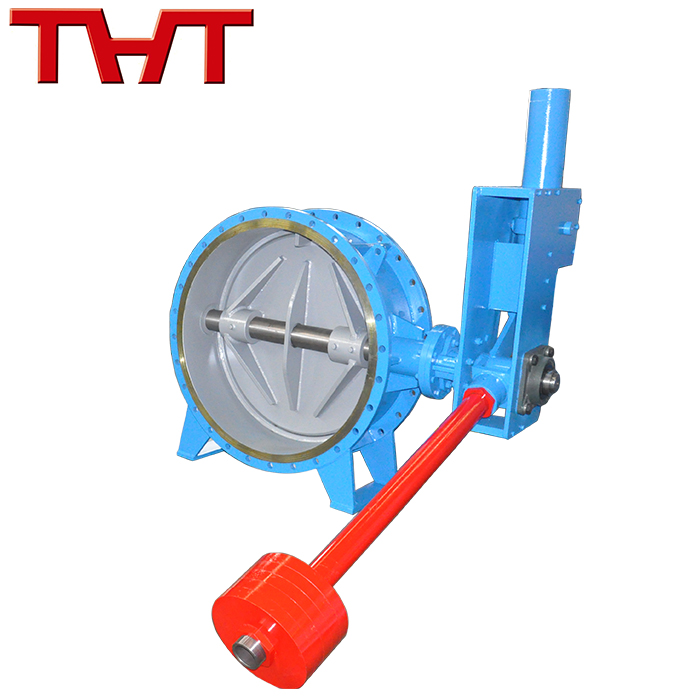

Wafer Pneumatic Actuated Triple Offset Butterfly Valve

- THT

- Tianjin,China

- 30 days

- 3000

▶▷A sealing ring, ensuringtightness in the seat, forms a sandwich of stainlesssteel sheets layered witha soft filler of graphite. This composition is able to withstand high temperatures and ensures excellent resilience of the sealing element even during significant fluctuations of medium temperature and pressure.

▶▷The packing system consists of a series of soft graphite sealing rings preventing leakage around the shaft. Graphite is a material which perfectly seals and resists high temperatures. Optimization of the ratio between tightness around the shaft and the actuating torque can be easily achieved by tightening or loosening the nuts holding the packing flange.

▶▷Spirally wound stainless steel band with a soft graphite filler guarantees a perfect seal even with large temperature and pressure fluctuations inside the pipe.

Wafer Pneumatic Actuated Triple Offset Butterfly Valve

The wafer pneumatic autuated triple offset butterfly valves design ensures safe function and tightness even in case of changing temperatures or in case of pressure peak. This triple offset butterfly valve also eliminates friction in the seat area when opening andclosing the valve, minimizing wear of the sealing elements, and significantly prolonging the servicelife of the valve. The first offset shifts the axis of the shaft rotation off the plane that lies on thepipeline axis. The second offset moves the center plane of the closing element parallel to its flatsurface outside of the axis of its rotation. The third offset deflects the axis of rotational symmetryof the seat surface outside of the axis perpendicular to the flat surface of the disc, running throughits center. A set of all these offsets results in specific butterfly valve properties such as friction eliminationduring opening/closing cycle, ideal contact of disc and seat in closed position and its sophisticated geometry naturally prevents the disc from moving beyond the safe limit and directly defines thecorrect alignment of sealing elements.

| Body | WCB/ZG1Cr18Ni9Ti |

| Disc | WCB/ZG1Cr18Ni9Ti |

| Seat | Stainless steel + flexible graphite, PTFE |

| Cover | 1Cr18Ni9Ti |

| Gasket | 1Cr18Ni9Ti |

| Stem | 1Cr13/1Cr18Ni9Ti |

| Yoke | WCB |

| Packing | Graphite/PTFE |