Zero Leakage Spectacle Line Blind Valve For Gas

- THT

- Tianjin

- 30 days

- 2000

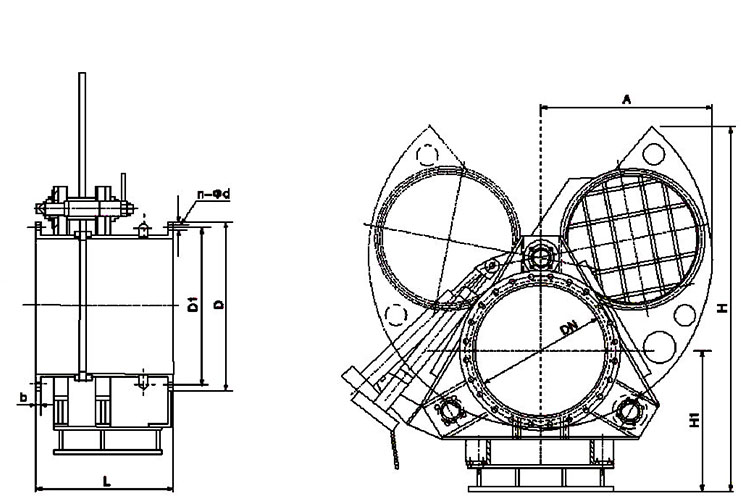

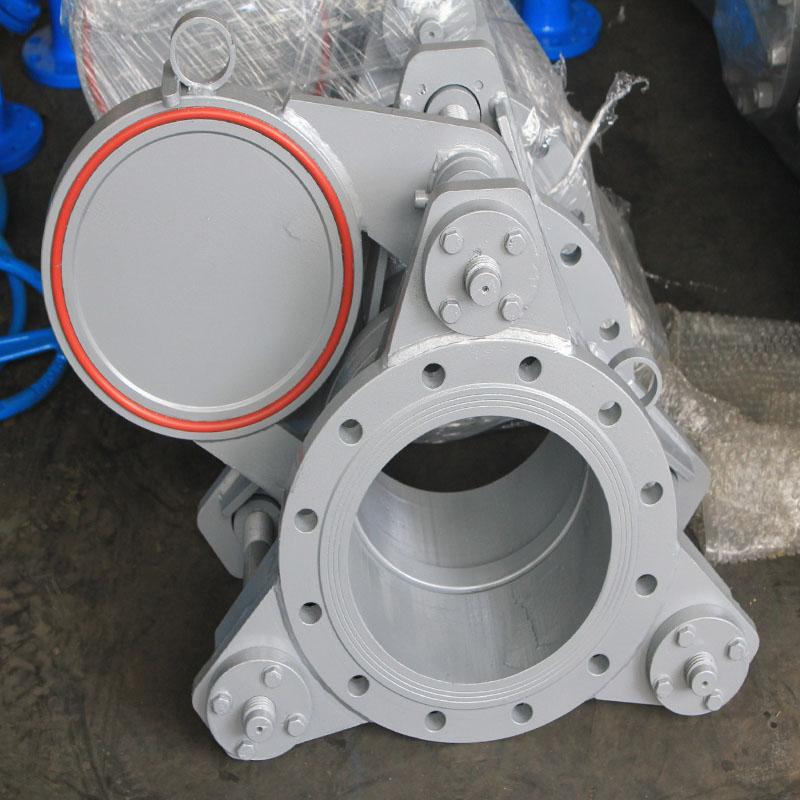

1.Simplified design, ruggedly and dependably built, easy to operate and economical to maintain – are the principal advantages of the zero leakage blind valve. The blind valve will render an absolute tight shut-off in blast furnace, basic oxygen, open hearth or other gas mains. The blind valve is designed for vertical operation in a horizontal main – with rollers and other daptations provided for horizontal operation in a vertical main.

2.When in the closed position, a definite separation on each side of the goggle plate is assured – to prevent leakage of gas from one side of the blind plate to the other. Should leakage occur between the blind plate and the clamping or stationary frames (due to improper clamping, for example), leakage will be admitted to the atmosphere and not around the blin plate to the depressurized side of the valve.

Zero Leakage Spectacle Line Blind Valve For Gas

The blind valve can be easily operated by one man, as follows:

1. unclamp the valve by turning the clamping drive chainwheel counterclockwise;

2. more the goggle plate to the desired position with the goggle plate chainwheel;

3.reclamp the valve by turning the clamping drive chainwheel clockwise. This entire operation take approximately five to seven minutes to complete.

| Size | DN200-DN1000 |

| Pressure | PN0.5-PN2.5 |

| Temperature | -20~100℃ -20~200℃ -20~250℃ |

| Medium | gas, Toxic and harmful gas |

| Body material | carbon steel |

| Stem material | Alloy steel |

Tianjin Tanggu Jinbin Valve Co., Ltd. was founded in 2004, with registered capital of 113 million yuan, 156 employees, 28 sales agents of China,covering an area of 20,000 square meters in total, and 15,100 square meters for factories and offices.It is a valve manufacturer engaged in professional R&D, production and sales,a joint-stock enterprise integrating science, industry and trade.

The company now has 3.5m vertical lathe, 2000mm * 4000mm boring and milling machine and other large processing equipment, multi-functional valve performance testing device and a series of perfect testing equipment such as physical.