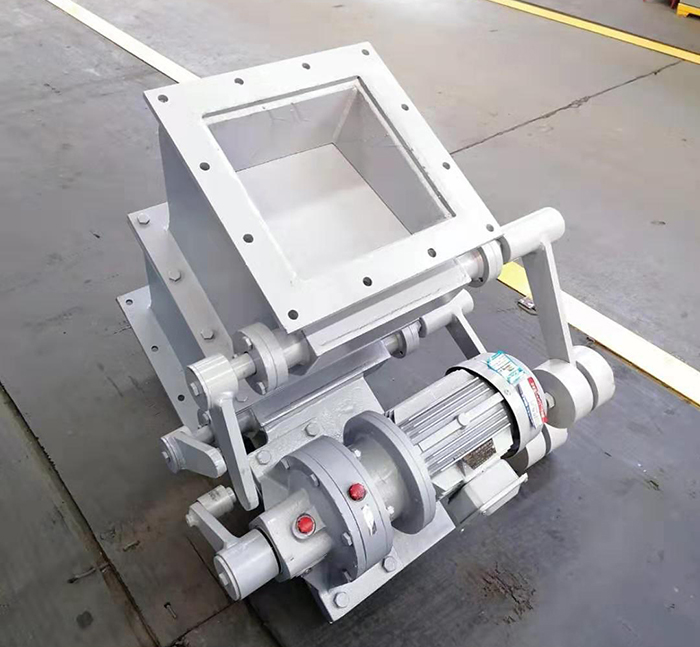

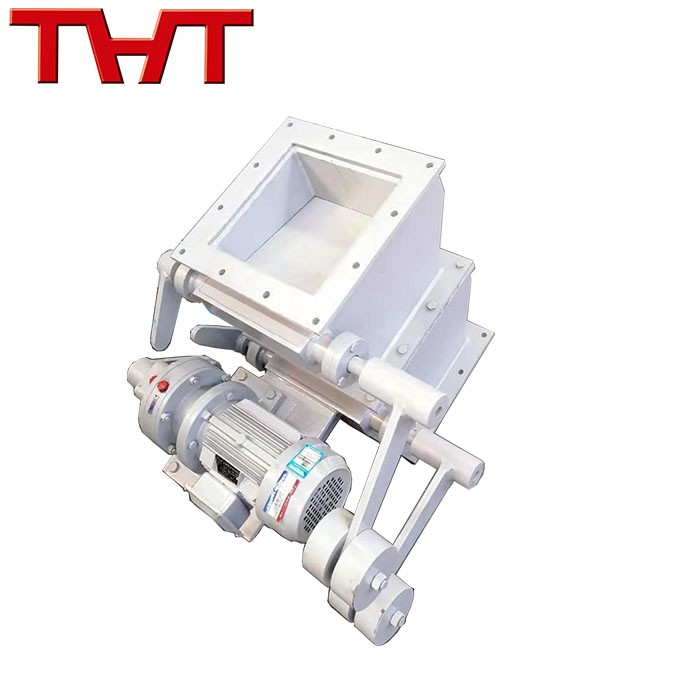

Cs Motorised Flow Control Gate

- THT

- Tianjin, China

- 25 days

- 2000

The Cs Motorised Flow Control Gate valve plate has two sealing surfaces. The two sealing surfaces of the most commonly used mode gate valve form a wedge. The wedge angle varies with the valve parameters, which is usually 50. The wedge gate of the wedge gate valve can be made into a whole, which is called rigid gate; it can also be made into a ram which can produce slight deformation, so as to improve its processability and make up for the deviation of sealing surface angle in the processing process, This kind of gate is called elastic gate plug valve. When closing, the sealing surface can only rely on the medium pressure to seal, that is, the sealing surface of the gate will be pressed to the seat on the other side to ensure the sealing of the sealing surface. This is self sealing. Most of the plug-in valves are forced to seal, that is, when the valve is closed, the ram should be forced to the valve seat by external force to ensure the sealing performance of the sealing surface.

Cs Motorised Flow Control Gate

The Cs Motorised Flow Control Gate is widely used in building materials, metallurgy, chemical industry, electric power and other industries.

The Cs Motorised Flow Control Gate is used as the discharge device of ash hopper of all kinds of equipment and the feeding and discharging device of various grinding machines, dryers and silos to prevent the wind from blowing in.

The Cs Motorised Flow Control Gate valve plate has two sealing surfaces. The two sealing surfaces of the most commonly used mode gate valve form a wedge. The wedge angle varies with the valve parameters, which is usually 50. The wedge gate of the wedge gate valve can be made into a whole, which is called rigid gate; it can also be made into a ram which can produce slight deformation, so as to improve its processability and make up for the deviation of sealing surface angle in the processing process, This kind of gate is called elastic gate plug valve. When closing, the sealing surface can only rely on the medium pressure to seal, that is, the sealing surface of the gate will be pressed to the seat on the other side to ensure the sealing of the sealing surface. This is self sealing. Most of the plug-in valves are forced to seal, that is, when the valve is closed, the ram should be forced to the valve seat by external force to ensure the sealing performance of the sealing surface.

| Size | 150*150-800*800 |

| Strength test pressure | 0.15mpa |

| Suitable medium | Solid particles, dust |

| Suitable temperature | ≤300℃ |

| Leakage rate | ≤1% |

| Discharge capacity | 1.5-250m3/h |

1. Use feeler gauge to measure the average clearance of each point ≤ 0.12mm.

2. Adjust the thickness of part No. 13 to ensure the axial fit of the shaft.

3. According to the required pressure of valve plate, adjust the distance of iron distribution on the crank to achieve accurate opening and closing without jamming.

4. After the valve assembly is qualified, rivet the thread of Part 20 to prevent loosening.

5. The non machined surface shall be coated with anti rust primer twice, and then the top coat (gray paint) shall be sprayed twice.

| Body | Carbon steel |

| disc | Carbon steel |

| Heavy hammer | Carbons steel |

| Electric actuator |