Knife Gate Valve

-

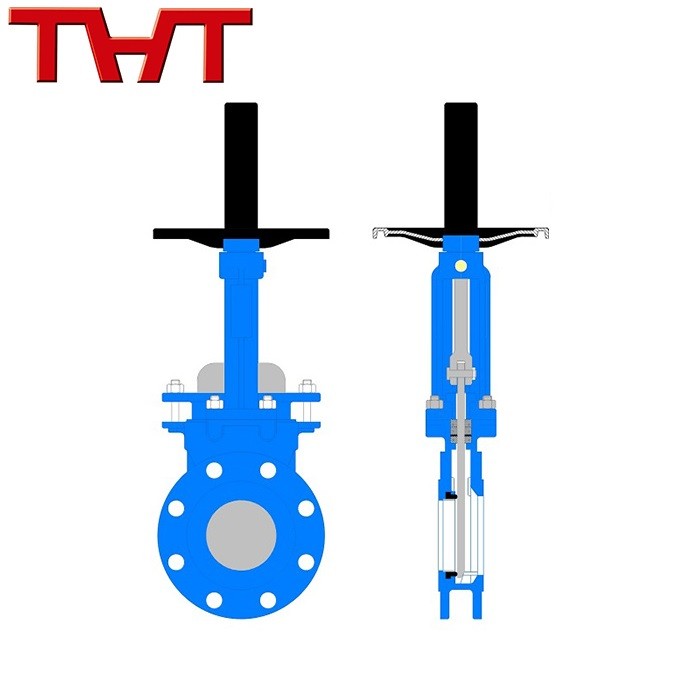

Spur gear PN16 flange ends ss316L knife gate valve

The main feature is a floating self-sealing, biaxial compression enabling bi-direction alsealing, high tightness. Easy to leak, has a smallerinstallation space, work pressure is low, easy accumulation of debris, high pressure gate no vibration,nonoise, linear channel, flow resistance, no pressure loss,the gate is closed, reliable media ram pressure to thepressure pushing the other side of the seat to ensurethe sealing surface, structure, small size, light weighteasy to install, easy disassembly and maintenance, etc

Email Details -

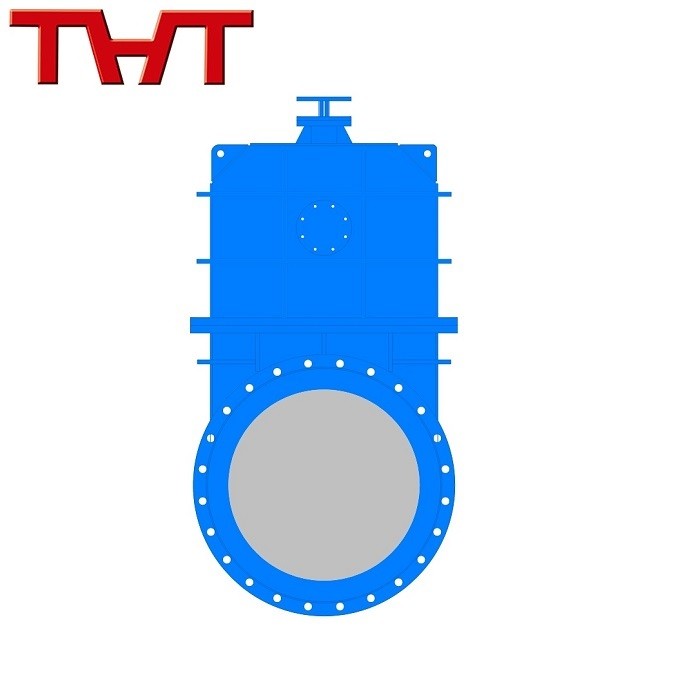

Flange Type rising stem Knife Gate Valve

Flange end knife gate valve are single valve body, one-time molding,suitable for water, mud, solid particles,sewage.

Email Details

SS 304 flange knife gate valve is uni-directional, body material can use carbon steel,cast steel,CF8,CF8M;seal material can choose EPDM,NBR,metal to metal ect.

Flange knife gate valve face to face is smaller,and the total weight is light.

Application temperature: -10℃-80℃

Nominal pressure: 0. 25MPA, 0. 6MPA, 1.0MPA -

Welding process flanged carbon steel Knife Gate Valve

The welding knife gate valve is bi-directional, can used in high pressure system.

Email Details

For welding knife gate valve welding quality, we can do NDT, PT inspection, UT testing, MT and X-ray flaw detection according to customer requirements.

Jinbinvalve carry out shell pressure test and sealing pressure test in strict accordance with the standard API598 or GB/T13927 -

WCB manual operated lug Knife Gate Valve

WCB manual operated lug Knife Gate Valve is Bi-directional, Zero Leakage, withstanding high differential pressure and full bore Valve with minimal seat cavity for maximun flow capactiy.

Email Details

No groove is designed on the valve seat, it can prevents accumulating media on the sealing surface. And thus avoids sealing surface leakage or disc blockage caused by media accumulation.

This kind of knife gate valve integrated body structure with precision casing.

The U-shaped resilient seat of knife gate valve is embeded into the body and is well-connected with the gate, and the friction force is reduced during the upard and downward movements of the gate. This greatly prolongs the using life of the seat and realizes bi-directional sealing. -

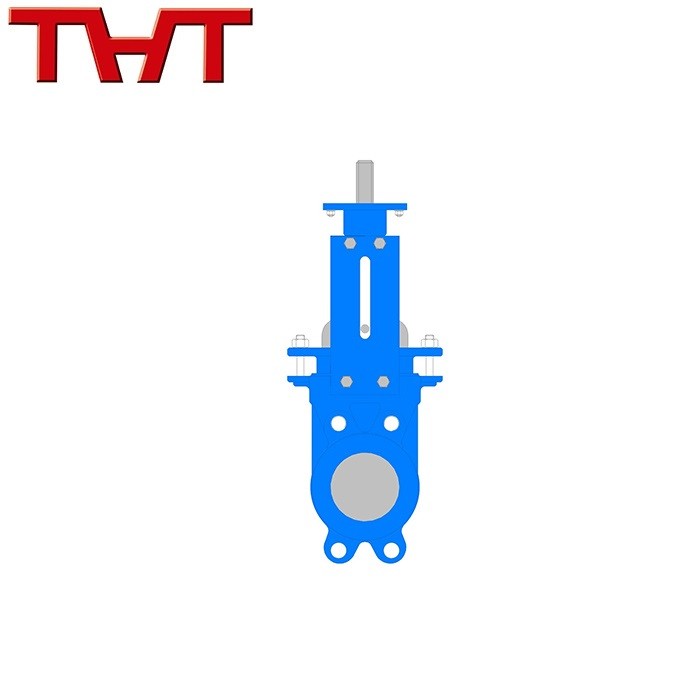

wafer ductile iron Knife Gate Valve

Non-rising stem knife gate valve have a stem nut on the disc,when turn the stem by hand,the disc will go up and down with the stem nut,this design used where the installation space is limited.

Email Details

We have some large diameter knife sluice gate valve body in stocked,so we can provide short lead time for our customers.

All the flange knife gate valve will tested one by one before shipping,test according to API598 GB/T13927 ext.

Body test 1.5*PN,seal test 1.1*PN, if the knife gate valve is bi-directional, then we will test two side of seal. -

Electric actuated ductile iron V- port knife gate valve

knife gate valve used lost foam casting technology,one step molding,low cost and reliable casting quality.

Email Details

Jinbinvalve apply float retaining ring for cast steel knife gate valve seal, which design ensured bi-directional of the valve.

The roller shaped stem ensures that the valve can be operated easily even under the maximum pressure.

knife gate valve can be installed in the middle of the pipe or at the end of the pipe. The structure is firm and can be used without reducing the pressure level. -

ductile iron wafer knife gate valve with pneumatic actuator

knife gate valve used lost foam casting technology,one step molding,low cost and reliable casting quality.

Email Details

Jinbinvalve apply float retaining ring for cast steel knife gate valve seal, which design ensured bi-directional of the valve.

The roller shaped stem ensures that the valve can be operated easily even under the maximum pressure.

knife gate valve can be installed in the middle of the pipe or at the end of the pipe. The structure is firm and can be used without reducing the pressure level. -

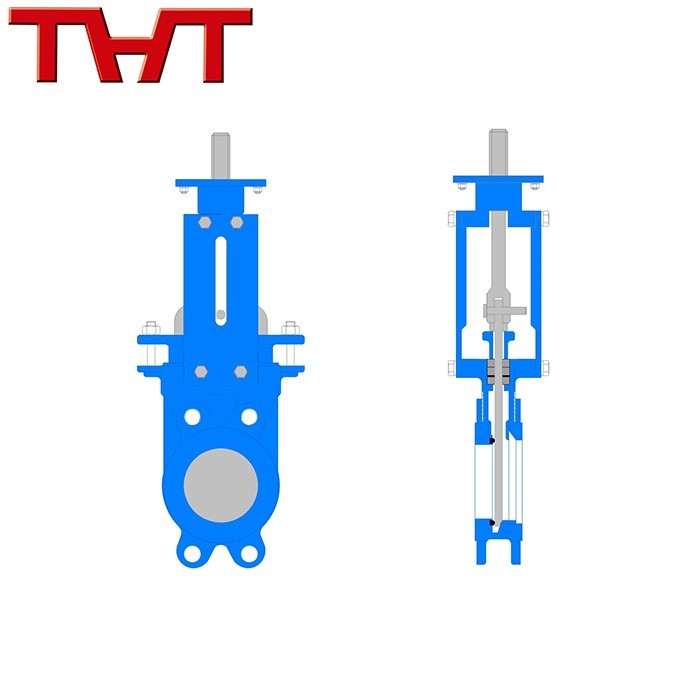

wafer manual operated Knife Gate Valve

1. It adopts the wafer structure, small volume and light weight.

Email Details

2. The fully open channel can prevent the medium from depositing in the valve.

3. The newly developed U-ring can ensure the good sealing performance of the valve. -

Rising Stem Knife Gate Valve

1. The knife gate valve adopts integral design, with small fluid resistance and flexible and convenient operation.

Email Details

2. The screw drive of manual knife gate valve adopts double plane bearing design, which greatly reduces the transmission friction and makes the valve open easily and smoothly.

3. Movable seal is used for the sealing seat of knife gate valve, and O-ring pre tightening is used to provide pre tightening force, which makes the sealing seat close to the valve disc, greatly reduces the leakage, and has automatic compensation function for the wear of sealing pair in long-term use, so as to improve the service life.

4. Fixed guide claw, no groove design, not easy to cause media accumulation or jamming.

5. The valve seat can choose metal hard seal or soft seal according to the needs of medium and working condition: the surface of the gate is treated with chromium plating or ion nitriding to make the gate more wear-resistant and the service life of the sealing surface longer; Soft seal can be PTFE seat or reinforced PTFE seat or EPDM, NBR, good sealing and corrosion resistance.

6. Wide range of media: good sealing performance, strong economic practicability, manual operation, pneumatic operation, electric operation, wide range of application.